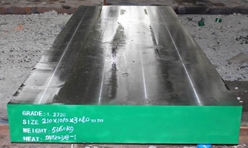

1.2738 718 P20+Ni Pre-hardened Plastic Mold Steel Block

1.2738 718 P20+Ni Pre-hardened Plastic Mold Steel Block

1 Introduction

1.2738 Pre-hardened Plastic Mold Steel, hardness in as-delivered condition 280 to 325 HB. Good machinability, suitable for texturing, improved through hardening in comparison to 1.2311, good polishability.

2 1.2738 Applications

Large plastic moulds with deep engravings and intensive impacts on the core. Pre-hardened Plastic Mold Steel is the logical development of 1.2311, a pre-hardened plastic mould steel for use in large moulds, which also have to display high core strength. The additional nickel content of 1 % increases through hardening. Formadur 2738 ia a micro-alloyed, vacuum-degassed steel with the following excellent features: good machinability, outstanding polishability, good texturing properties.

1.2738 mold steel materials are generally used for relatively low temperature applications such as die casting dies and injection moulds, synthetic plastic moulds dies, especially for large plastic moulds higly stressed in core, hydroforming tools, such as up to 400 mm in the construction of plastic moulds. DIN 1.2738 is suitable for nitriding and chrome plating.

3 Quality Standard

: ASTM A681 – 08 Standard Specification for Tool Steels Alloy.

4 All Grades Comparison

| ASTM A681 | Werkstoff | ASSAB |

|---|---|---|

| P20+Ni | 1.2738 | 718 |

5 1.2738 Chemical Composition(%)

| C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 0.030 max | 0.030 max | 1.80-2.10 | 0.90-1.20 | 0.15-0.25 |

6 Mill′s test certificate

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

DIN 1.2738 steel is one kind of plastic mold steel, equivalent to AISI P20+Ni tool steel. While Nickel, chromium and molybdenium are the alloying elements for hardness and toughness. 1.2738 tool steel is specially designed for plastic mold industry, especially for big steel mold parts.

DIN 1.2738 tool steel is usually supplied as pre-hardened/quenched and tempered 280 – 320 HB hardness condition

With good machinability, DIN 1.2738 steels is with better polishability compared to 1.2312 (AISI P20+S).

Material 1.2738 can be through nitrogenation and flame hardening treatment in order to increase the hardness and wearability of mould surface.

The steel 1.2738 is melted in an electrical furnace and refined with VOD or DH device.