INCONEL 718 SHEETS, PLATES & COILS

Inconel 718 Sheets, Plates

With over 35 years of industry expertise, Fushun has the industry knowledge and resources to find you the metal products that you need for your specific industry applications. We are in stock and ready to quickly deliver hard-to-find metals. Our ISO 9001-certified metal supply is one of the most comprehensive selections on the market. We provide timely customer support and quick delivery on all quantities of our in stock products.

Contact us for more information regarding our nickel alloy manufacturing and distribution options. Fushun is your trusted nickel alloy supplier for all types of Nickel alloy material.

Introduce

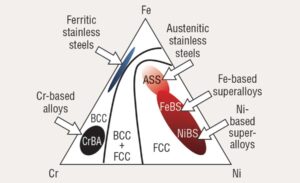

Inconel 718 is an age-hardenable Alloy-chromium alloy that combines corrosion resistance with high strength and good fabricability. It has high creep-rupture strength at temperatures up to 700 ℃. Its excellent relaxation resistance contributes to its application in springs. 718 Inconel Sheet, ASME SB168 Inconel 718 Sheets, Inconel 718 Coils, 718 Inconel Cold Rolled Sheets Dealer, Inconel® Alloy 718 Plates, ASTM B168 Alloy 718 Sheets and Plates, Inconel Alloy 718 Sheets Exporter, Inconel® 718 Hot Rolled Plates Suppliers in china.The Inconel 718 Sheets, Plates & Coils are in generally molybdenum-chromium-nickel alloy that got designed and developed so as to resist vast corrosive environmental ranges. It even shows resistance in a crevice and pitting corrosive environment. This nickel-based steel alloy shows exceptional creep rupture and high tensile plus yield properties at elevated temperatures. At cryogenic temperature, the product can be used for long term service up to temperature range of 1200 degree F. Permit to age hardening that allows annealing, as well as welding, distinguish Inconel 718 with niobium addition.

Application

The alloy is used in jet engine and high-speed airframe parts such as wheels, buckets and spacers, and high-temperature bolts and fasteners. Inconel 718 is also used in the oil and gas drilling and production industries due to its high strength and resistance to chlorides, stress corrosion and sulfide stress cracking. Within these industries the alloy has been used for valves, pump shafts and wellhead components.Inconel 718 Slit Coil, Inconel® 718 Sheets, Inconel Alloy 718 CR Plates, WNR. 2.4668 Sheets, Inconel 718 Sheets, UNS N07718 Plates, Alloy 718 Circle, Inconel Alloy 718 Plates Distributors, JIS NCF 718 Sheets and Plates Manufacturer in china. The addition of molybdenum and niobium makes the alloy stiffen thus providing high strength with no heat treatment. They can be readily welded and fabricated in precipitated or annealed hardened conditions. These superalloys are made available in various dimensions, specifications, and sizes that ultimately make is suitable for marine engineering, chemical processing, and other applications too.

Heat-Treat Process

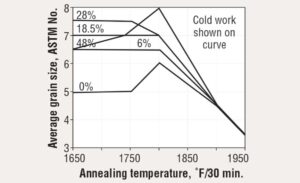

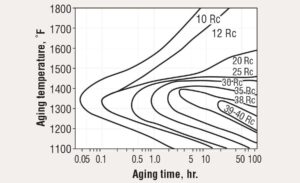

Inconel® 718 is typically purchased in the mill- or solution-annealed condition. In some instances, it has a stress-relief operation performed on it prior to fabrication and heat treatment. The solution anneal is followed by a precipitation (age) hardening step. Precipitation of secondary phases (e.g., gamma prime and gamma double-prime) into the metal matrix hardens the material. The precipitation of nickel-aluminum, nickel-titanium and nickel-niobium phases is triggered by aging in the temperature range of 600-815˚C (1100-1500˚F). The key to the heat-treatment process is to be sure these age-hardening constituents are fully in solution at high temperature (i.e., fully dissolved in the matrix), otherwise precipitation will not result in full strength.Two heat treatments are common (although slight temperature variations of these recipes are often employed).Solution anneal at 925-1010˚C (1700-1850˚F) followed by rapid cooling (usually in water). This is followed by precipitation hardening at 720˚C (1325˚F) for 8 hours, furnace cooling to 620˚C (1150˚F) and holding for 10 hours followed by air cooling.

Solution anneal at 1040-1065˚C (1900-1950˚F) followed by rapid cooling (usually in water). This is followed by precipitation hardening at 760˚C (1400˚F) for 10 hours, furnace cool to 650˚C (1200˚F) and holding for 10 hours followed by air cooling.Solution heat treatments are typically done in low-dew-point argon or vacuum furnaces, often with all-metal hot zones to avoid discoloration. The effect of annealing for 30 minutes on the grain size (Fig. 2) of sheet varies with temperature. Also, aging response of Inconel® 718 is rather slow in comparison with that of aluminum-titanium-hardened alloys. Thus, in most sizes, the alloy can be heated and cooled through the aging temperature range at normal speeds yet retain softness and ductility. The effect of aging time and temperature on the hardness of annealed sheet (Fig. 3) reflects this.

Standards

718 Sheet, Coil and Plate: UNS N07718, AMS 5596, ASTM B 670, ASME SB 670, B50TF14,

718 Round Bar: UNS N07718, AMS 5662, ASTM B 637, B50TF15, B50809D (Power Generation)

other:AMS 5662, AMS 5663, AMS 5832, AMS 5962, ASTM B637, GE B14H89, ISO 15156-3, (NACE MR 0175)

Grades 718 Inconel Sheets & Plates, Coils Specification :

Specifications : ASTM B168 / ASME SB168

Standards : ASTM, ASME and API

Inconel Sheet : thickness range from .008″ to .0125″

Inconel Plate : thickness ranges from .0125″ to 5.00″

Size : 15NB to 150NB In

Tempers : Annealed, 1/4, 1/2 Hard, 3/4 Hard, Full Hard

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc

Form : Coils, Foils, Rolls, Strip, Flats, Blank (Circle), Ring (Flange) etc.

| Density | 8.19g/cm³ | 0.296 lb/in³ |

| Melting Point | 1336°C | 2437°F |

| Coefficient of Expansion | 13.0 μm/m °C (20 – 100°C) | 7.2 x 10-6 in/in °F (70 – 212°F) |

| Modulus of Rigidity | 77.2 kN/mm² | 11197 ksi |

| Modulus of Elasticity | 204.9 kN/mm² | 29719 ksi |

| Properties | ||||

|---|---|---|---|---|

| Condition | Approx. tensile strength | Approx. operating temperature depending on load^^ and environment | ||

| N/mm² | ksi | °C | °F | |

| Annealed | 800 – 1000 | 116 – 145 | – | – |

| No 1 Temper | 1000 – 1200 | 145 – 175 | – | – |

| Spring Temper | 1250 – 1550 | 180 – 225 | – | – |

| No 1 Temper + Annealed + Aged | 1250 – 1450 | 181 – 210 | -200 to +550 | -330 to +1020 |

| No 1 Temper + Aged | 1520 – 1720 | 220 – 250 | Contact Alloy Wire Technical Dept | |

| Spring Temper + Annealed + Aged | 1250 – 1450 | 181 – 210 | -200 to +550 | -330 to +1020 |

| Spring Temper + Aged | 1700 – 1950 | 247 – 283 | Contact Alloy Wire Technical Dept | |

Key Features

Good creep rupture strength at high temperatures

Higher strength than Inconel X-750

Better mechanical properties at lower temperatures than Nimonic 90 & Inconel X-750

Age hardenable

High temperature dynamic applications

Chemical Composition

| Ni | Fe | Cr | Cu | Mo | Nb | C | Mn | P | S | Si | Ti | Al | Co | B |

| 50.00-55.00 | Remainder | 17.00-21.00 | .30 max | 2.80-3.30 | 4.75-5.50 | .08 max | .35 max | .015 max | .015 max | .35 max | .65-1.15 | .20-.80 | 1.00 max | .006 max |

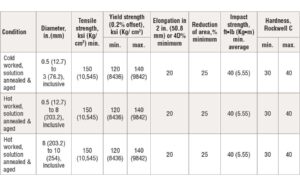

Mechanical Properties

| Condition | Approx. tensile strength | Approx. operating temperature depending on load^^ and environment | ||

| N/mm² | ksi | °C | °F | |

| Annealed | 800 – 1000 | 116 – 145 | – | – |

| No 1 Temper | 1000 – 1200 | 145 – 175 | – | – |

| Spring Temper | 1250 – 1500 | 180 – 225 | – | – |

| No 1 Temper + Annealed + Aged | 1250 – 1450 | 181 – 210 | -200 to +550 | -330 to +1020 |

| No 1 Temper + Aged | 1520 – 1720 | 220 – 250 | Contact Alloy Wire Technical Dept | |

| Spring Temper + Annealed + Aged | 1250 – 1450 | 181 – 210 | -200 to +550 | -330 to +1020 |

| Spring Temper + Aged | 1700 – 1950 | 247 – 283 | Contact Alloy Wire Technical Dept | |

| Heat Treatment of Finished Parts | |||||

|---|---|---|---|---|---|

| Condition as supplied by Alloy Wire | Type | Temperature | Time (Hr) | Cooling | |

| °C | °F | ||||

| No. 1 or Spring Temper | Anneal Age Harden Total Age |

980 720 620 |

1800 1330 1150 |

1 8 18 |

Air Furnace Air |

| No. 1 or Spring Temper (for ISO 15156-3 / NACE MR 0175) |

Anneal Age Harden |

1010 790 |

1850 1455 |

2 6 |

Air Air |

| No. 1 Temper or Spring Temper | Age Harden Total Age |

720 620 |

1330 1150 |

8 18 |

Furnace Air |

The Heat Treatment of Inconel® 718

The Heat Treatment of Inconel® 718 2

The Heat Treatment of Inconel® 718 3

The Heat Treatment of Inconel® 718 4

Heat treatments

Heat treatments may be adjusted to give required properties. For the best combination of tensile and stress rupture properties, the following quite complex cycle is recommended :

1 hr at 1750/1800ºF (955/980ºC) and air cool, then 8 hrs at 1325ºF (720ºC) and cool at 100ºF/hr (56ºC/hr) to 1150ºF (620ºC), hold for 8 hrs and air cool.

For the best room temperature and cryogenic tensile properties, the cycle is :

1-2hrs at 1950ºF (1065ºC) and air cool, then 8 hrs at 1325ºF (720ºC) and cool at 100ºF/hr (56ºC/hr) to 1150ºF (620ºC), hold for 8 hrs and air cool.

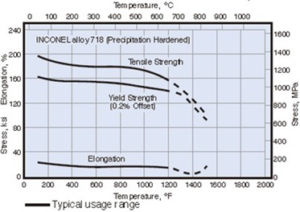

Temperature dependence of mechanical properties for the aged Inconel 718

Hot Forming

Because of its strength, INCONEL alloy 718 is more resistant than most materials to deformation during hot forming. It is readily hot-worked if sufficiently powerful equipment is used. Hot forming is performed in the 1650°-2050°F temperature range. In the last operation, the metal should be worked uniformly with a gradually decreasing temperature, finishing with some light reduction in the 1650°-1750°F range. This procedure is necessary to ensure notch ductility in stress-rupture applications when material has been annealed and aged.

Inconel 718 sheets, plates & coils Testing and packaging

The tests conducted on Inconel 718 sheets, plates & coils are chemical analysis, mechanical testing, flattening test, intergranular corrosion test, micro test, and macro test. It finally got packed in wooden boxes and crates.

Quality & Testing

Fushun supply Certification with all shipments, containing full chemical analysis and also mechanical test results if requested.

All incoming material is visually inspected and PMI (Positive Material Identification) tested before processing begins and all our production material is checked during each stage of processing.

All incoming orders are produced to the individual customer specification, some of which may involve processing sample batches for testing prior to full production.

Final Inspection carried out on all finished material to include:

Visual inspection

Dimensional checks

PMI (Positive Material Identification)

Mechanical tests

Nickel Alloy Material Available Formats

Fushun offers pure Nickel alloy materials in a variety of forms, including:

Seamless & welded pipe

Seamless & welded tube

Bar

Wire

Sheet

Plate

Forgings

Pipe fittings

Flanges

Weld Rod

Nickel Alloy Supply Quantities for Single Items or Full Bills

At Fushun, we can supply single items or full bills of nickel alloy materials for most any project. No inquiry is too small. We offer quick responses to customer inquiries and specialize in the rapid delivery of both large and small quantities of nickel alloy products.

Contact Fushun for Nickel Alloy Materials Today

Contact us for more information regarding our nickel alloy material options, or request a quote for further pricing details today. Fushun is your trusted nickel alloy supplier and manufacturer of premium nickel alloy materials.