1.6582 34CrNiMo6 Alloy Steel

1.6582 34CrNiMo6 Alloy Steel

EN 34CrNiMo6 Steel is an important alloy engineering steel grade as per BS EN 10083-3:2006. 34CrNim06 steel has high strength, high toughness and good hardenability. EN / DIN 34CrNiMo6 alloy steel has the stability of resistance to overheating, but the white sensitivity of 34CrNiM06 is high. It also has the temper brittleness, so the weldability of 34CrNiMo6 material is poor. The steel 34CrNiMo6 needs the high temperature preheating before welding in order to eliminate the stress after welding processing.

Supplying Size:

Rolled: Diameter 40-200mm

Forged: Diameter 80-600mm

EN 34CrNiMo6 Steel Standards And Equivalents

| BS EN 10083 -3: 2006 | 34CrNiMo6 / 1.6582 | ASTM A29: 2004 | 4337 |

| BS EN 10250 – 3: 2000 |

EN/DIN 34CrNiMo6 Steel Chemical Composition Properties

| BS EN 10083 – 3:2006 | 34CrNiMo6 /1.6582 |

C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.025 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | ||

| BS EN 10250-3:2000 | C | Mn | Si | P | S | Cr | Mo | Ni | |

| 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.035 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | ||

| ASTM A29: 2004 | 4337 | C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.30-0.40 | 0.6-0.8 | 0.20-0.35 | 0.035 max | 0.040 max | 0.70-0.90 | 0.20-0.30 | 1.65-2.00 |

Mechanical Properties of EN/DIN 34CrNiM06 / 1.6582 Alloy Steel

| Properties | < 16 | >16 – 40 | >40 – 100 | >100 – 160 | >160 – 250 |

| Thickness t [mm] | < 8 | 8<t<20 | 20<t<60 | 60<t<100 | 100<t<160 |

| Yield strength Re [N/mm²] | min. 1000 | min. 900 | min. 800 | min. 700 | min. 600 |

| Tensile strength Rm [N/mm2] | 1200 – 1400 | 1100 – 1300 | 1000 – 1200 | 900 – 1100 | 800 – 950 |

| Elongation A [%] | min. 9 | min. 10 | min. 11 | min. 12 | min. 13 |

| Reduction of area Z [%] | min. 40 | min. 45 | min. 50 | min. 55 | min. 55 |

| Toughness CVN [J] | min. 35 | min. 45 | min. 45 | min. 45 | min. 45 |

Heat Treatment of 34CrNiMo6 Engineering Steel

Quenched and Tempered (Q+T) of 34CrNiMo6 Steel

Heat 34CrNiMo6 round steel slowly to the temperature of 850°C;

Soak at this hardening temperature quench in oil;

Temper as soon as 34CrNiMo6 steels reach room temperature.

Heat uniformly to the suitable temperature;

Withdraw from the furnace and cool in the air.

The usual tempering temperature is 600°C which depending on the actual requirements.

Forging of DIN 34CrNiMo6 / 1.6582 Steel

Hot forming temperature: 1100-900oC.

7.Machinability of Steel 34CrNiMo6

Machining is best done with this 1.6582 alloy steel in the annealed or normalized and tempered condition. It can be machined by all conventional methods.

8.Welding The alloy materials can be fusion or resistance welded. Preheat and post heat weld procedures should be followed when welding this alloy by established methods.

EN DIN 34CrNiMo6 steel is used to make tools which demands good plasticity and high strength. It is usually selected to make the big size and important parts, such as heavy machinery axle,turbine shaft blade, high load of transmission parts, fasteners, crank shafts, gears, as well as heavily loaded parts for motor construction etc.Steel is reliable to supply engineering 34CrNiMo6 steels / 1.6582 engineering alloy steels. Please tell us your detailed requirements and have the best offer soon.

What is EN10083 1.6582 34CrNiMo6 Hardening Steel ?

Bright Bars are of 2 types-1. Cold Drawn and Peeled 2. Turned.In a Cold Drawn Bright Bar the Hot Rolled Bars are pickled and drawn through a Tungsten Carbide Die as Cold Rolled, no heating is required, that is why it is called a Cold Drawn Bright Bar.Secondly in Peeled / Turned Bright Bar the Hot Rolled Bar is fed into a Turning machine and the surface is turned / removed to the required size of the Dia. This is also a Cold process, no heating is required. Bright Bars can be further Ground Finished for special applications. Bright Bars have a smooth and a Bright surface with Accurate Tolerance on the Dia. Accurate Tolerance means the tolerance of the Dia is very restricted i.e 0.10 mm approximatly depending on the size of the Dia and as per the customer’s specific requirement. These are the reasons why a Bright Bar enjoys advantages over a Hot Rolled Bar. Bright Bars can be used in automatic Machines for making Steelcomponents whereas a Hot Rolled Bar cannot be used.

Heat Treatment

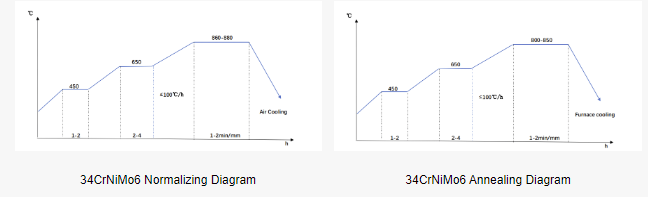

Normalizing:860℃-880℃,Cool in air

Soft Annealing:650℃-680℃,Cool in furnace,max. 248 HB

Full Annealing:800-850℃,Cool in furnace

Hardening:830 – 860°C,oil quench is recommended

Tempering:540°C – 660°C, cool in still air

Mechanical Property with Quenched and Tempered condition as per EN10083

| Size,mm | Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction,% | Charpy Impact,J |

| ≤16 | 1200-1400 | ≥1000 | ≥9 | ≥40 | – |

| 16-40 | 1100-1300 | ≥900 | ≥10 | ≥45 | ≥45 |

| 40-100 | 1000-1200 | ≥800 | ≥11 | ≥50 | ≥45 |

| 100-160 | 900-1100 | ≥700 | ≥12 | ≥55 | ≥45 |

| 160-250 | 800-950 | ≥600 | ≥13 | ≥55 | ≥45 |

Mechanical Property with Quenched and Tempered condition as per EN10250

| Thickness,mm | Tensile,Mpa | Yield,Mpa | Elongation,% | Charpy Impact,J |

| ≤160 | ≥800 | ≥600 | L:≥13 T:≥9 |

L:≥45 T:≥22 |

| 160-330 | ≥750 | ≥540 | L:≥14 T:≥10 |

L:≥45 T:≥22 |

| 330-660 | ≥700 | ≥490 | L:≥15 T:≥11 |

L:≥40 T:≥20 |

Mechanical Property of Testing Data for Quenched and Tempered condition

| Size mm | Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction,% | Charpy Impact,J | Hardness,HB |

| Φ200 | 925 | 740 | 18 | 61.5 | 104/108/118 | 302-323 |

| Φ280 | 925 | 740 | 18 | 63.5 | 106/103/101 | 286-309 |

| Φ350 | 905 | 725 | 20 | 64.5 | 112/110/111 | 288-312 |

| Φ430 | 825 | 650 | 17.4 | 54.5 | 89/105/113 | 270-275 |

| Φ575 | 785 | 590 | 20 | 50 | 97/91/76 | 270-272 |

Application:

High voltage bolts and nuts, crankshafts, camshafts, transmission axles, torsion bars, drive shafts, pump shafts, worm shafts, conveyor rollers, stems, pins, tie rods, clutch discs. Large-mass dies for hot stamping.1.6582 Steel is widely used in the aerospace industry for structural parts of flaps assembly, fuselage and landing gear, propeller plane axles.

Product Description:

1.6582 Steel is a heat treatable, low alloy steel containing nickel, chromium and molybdenum. It is known for its toughness and capability of developing high strength in the heat treated condition while retaining good fatigue strength. A very popular, versatile steel. It can be heat-treated to produce a wide range of tensile strength in moderate sections.

Transformation temperatures

| Temperature °C | |

| MS | 315 |

| AC1 | 725 |

| AC3 | 785 |

Heat treatment recommendations

| Treatment | Condition | Temperature cycle | Cooling/quenching |

| Hot forging | +AR | 880-1050oC | In air |

| Soft annealing | +A | 650-700oC | Slowly (15oC/h) until 600oC |

| Stress relieve annealing | +SRA | 450-650oC (appr. 50oC under tempering temperature) | In air |

| Hardening | +Q | 820-850oC | Quenching in oil |

| Tempering | +T | 540-680oC | In air |

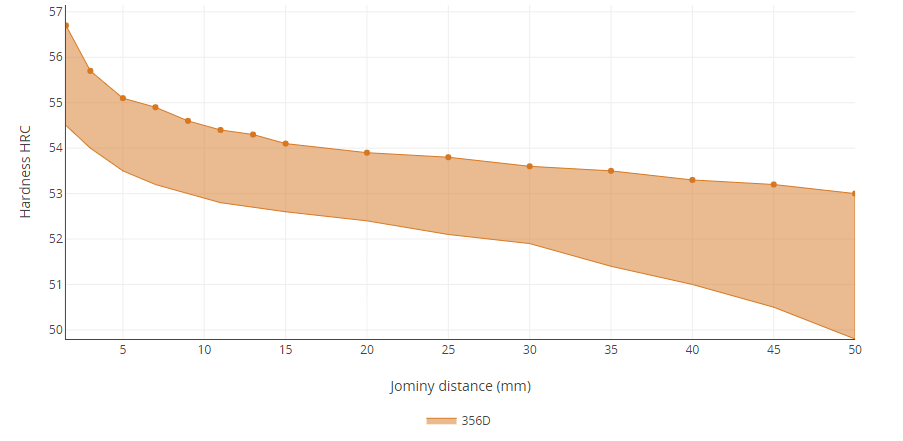

Hardenability

Steel cleanliness

| Micro inclusions |

|

Macro inclusions | |||||||||

| Applied standard | ASTM E45 | Applied standard | ISO 3763

(Blue fracture) |

||||||||

| Sampling | ASTM A295 | Sampling | Statistical testing on billets | ||||||||

| Maximum

average limits |

A | B | C | D | Limits | < 5 mm/dm2 | |||||

| Th | He | Th | He | Th | He | Th | He | ||||

| 2.0 | 1.5 | 0.8 | 0.1 | 0 | 0 | 0.5 | 0.4 | ||||

Steel cleanliness

| Micro inclusions – | Macro inclusions – | |||

| Applied standard | DIN 50602 K1 | Applied standard | 10 M Hz UST

(Ovako internal standard) |

|

| Sampling | Six random samples from final product dimension | Sampling | Statistical testing on billets | |

| Limits | The limit is dimension dependent. The average rating of six samples

should not exceed the limits given in the graph |

Limits | < 10 defects/dm3

> 0,2 mm FBH |

|

Other properties (typical values)

| Youngs module (GPa) | Poisson´s ratio (-) | Shear module (GPa) | Density (kg/m3) |

| 210 | 0.3 | 80 | 7800 |

| Average CTE 20-300°C (µm/m°K) | Specific heat capacity 50/100°C (J/kg°K) | Thermal conductivity Ambient temperature (W/m°K) | Electrical resistivityAmbient temperature (µΩm) |

| 12 | 460 – 480 | 40 – 45 | 0.20 – 0.25 |