S32750 Duplex Stainless Steel

Alloy 32750 (UNS S32750)

Description:

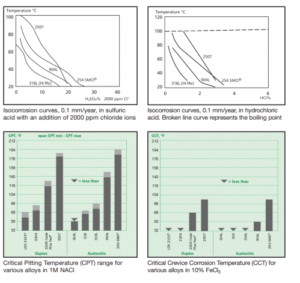

Alloy 32750 is a super duplex stainless steel supplied in the solution annealed condition. As a super duplex stainless steel, it combines the desirable aspects of both austenitic and ferritic grades. The higher chromium, molybdenum and nitrogen contents result in a Pitting Resistance Equivalent number (PREN) of >41, providing pitting and crevice corrosion resistance superior to austenitic and duplex stainless steels in almost all corrosive media, and a Critical Pitting Temperature exceeding 50°C.

Supplied in the annealed condition, it achieves yield strengths of 80ksi (550Mpa), greater than most austenitic and duplex stainless steel grades. It cannot be hardened by heat treatment but can be strengthened by cold working. It also exhibits a low coefficient of thermal expansion and higher heat conductivity than austenitic steels and is suitable for working temperatures up to 300°C. Alloy 32750 is listed in NACE MR 0175 for sour service and having gained ASME Approval for Pressure Vessel applications it can be used in a wide variety of applications.

Chemical Composition:

| Cr | Ni | Mo | Co | Nb (+Ta) | Ti | V | W | Cu | C | Mn | N | Si | P | S | Fe | Al | |

| Min | 24.50 | 6.00 | 3.00 | 0.50 | 0.24 | 0.10 | |||||||||||

| Max | 26.00 | 8.00 | 5.00 | 0.50 | 0.03 | 1.20 | 0.32 | 0.80 | 0.035 | 0.020 | Bal |

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

5 +AT: Solution annealed

6 +P: Precipitation hardened

Suface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

Mechanical Properties:

| 0.2% Proof Stress | 550 N/mm2 | 79.8 ksi |

| Tensile Strength | 800 N/mm2 | 116 ksi |

| Elongation, 5.65√S0 | 25% | |

| Reduction of area | 45% | |

| Hardness (Brinell) | <270 | |

| Impact Strength (Room Temp) | 80J | |

| Impact Strength (-46oC) | Longitidinal 45J (35J min) | |

| Transverse 45J (35J min) | ||

Notes:

Testing shall be carried out in accordance with ASTM A370 or EN ISO 6892-1 (tensile), EN ISO 6506-1 (hardness)

Minimum properties quoted (tested at room temperature in a longitudinal direction)

Testing performed on each melt of material per heat treatment batch

Hardness shall be in accordance with NACE MR 1075 with a maximum HRC of 25

ASTM G48A corrosion test (at 50°C) No pitting and < 3.0g/m2 weight loss (ASTM specification < 4.0g/m2)

Ferrite content 35-55%

Microstructure certified free from grain boundary carbides, sigma, chi and laves phases

Physical Properties:

| Density (Kg/m3) | 7810 |

| Magnetic Permeability (20°C) | 33 |

| Young’s Modulus (kN/mm2) | 199 |

| Specific Electrical Resistance, 20°C (µΩ.m) | 0.8 |

| Mean coefficient of thermal expansion, 20-300°C (m/m/oC) | 11.1 x 10-6 |

| Specific Heat, 20°C (J/kg.K) | 475 |

| Thermal conductivity, 20°C (W/m.K) | 14.2 |

Material to UNS S32750 is described as a super duplex stainless steel with a microstructure of 50:50 austenite and ferrite.

INTRODUCTION

The steel combines high mechanical strength (typically up to 570 MPa yield strength) and good ductility with outstanding corrosion resistance in marine environments. The alloy is supplied with a PREN (Pitting Resistance Equivalent) at >=40.0 which guarantees high resistance to pitting corrosion. In addition, the steel offers high resistance to crevice corrosion and stress corrosion cracking. Ambient and sub-zero (down to minus 50°C) notch ductility is good.

SUITABILITY

These attributes mean that this super duplex steel can be used successfully as an alternative to 300 series stainless steel (such as type 316), standard 22% Cr duplex steel (such as UNS S31803 / 1.4462 with PREN 33-34) and precipitation hardening stainless steels (typically 17/4PH).

TYPICAL APPLICATIONS

Commercial applications for this engineering material include:

Pumps, valves, chokes

Pipework/flanges

Connectors

Manifolds

Oil & gas components

We stock UNS S32750 in round bar, plate, sheet and round tube.

Super Duplex UNS S32750 is the most common super duplex grade in the market. UNS S32750 is a duplex stainless steel especially designed for service in aggressive chloride-containing environments. It has very good resistance to localized corrosion and stress corrosion cracking in combination with high mechanical strength. It is widely used in oil & gas, hydropower, pressure vessels, pulp & paper, structural components and chemical tankers.

APPLICATIONS

The main applications are for details with special requirements for high corrosion resistance.

UNS S32750 is characterized by:

• High resistance to stress corrosion cracking in halide containing environments.

• High resistance to pitting and crevice corrosion.

• High resistance to general corrosion.

• High mechanical strength.

• High resistance to erosion corrosion and corrosion fatigue.

MECHANICAL PROPERTIES

| Yield strength Rp0.2, MPa |

Tensile strength Rm, MPa |

Elongation [%] |

Hardness [HB] |

Impact, Charpy-V, -46ºC [J] |

Pre | |

| BAR | ≥ 550 | ≥ 750 | ≥ 25 | ≤ 310 | ≥ 45 | ≥ 40 |

| PLATE CR (COIL) | ≥ 550 | 750 – 1000 | ≥ 25 | ≤ 310 | ≥ 45 | ≥ 40 |

| PLATE HR (COIL) | ≥ 550 | 750 – 930 | ≥ 25 | ≤ 310 | ≥ 45 | ≥ 40 |

| PLATE (QUARTO) | ≥ 550 | 750 – 930 | ≥ 25 | ≤ 310 | ≥ 45 | ≥ 40 |

Super Duplex UNS S32750 is the most common super duplex grade in the market. UNS S32750 is a duplex stainless steel especially designed for service in aggressive chloride-containing environments with high mechanical strength.

Synopsis

UNS S32750 or 2507 Duplex is a super austenitic premium stainless that is similar to 2205 Duplex. 2507 Stainless Steel is composed of 25% Chrome and 7% nickel which causes the alloy to have an even higher corrosion resistance and longer life span. Along with it being corrosion resistant, UNS S32750 has a high resistance of cracking and pitting, and the yield and tensile strength make it comparable to nickel alloys.

Resistance

Large chromium levels as well as molybdenum content of 2507 Duplex makes this material very resistant to corrosive acidic elements. It implements great resistance to chloride SCC and is preferable to 2205 Duplex in both strength and corrosive resistance.

Processing

2507 Duplex material will be heat treated at climates ~2000°F. After heated, the substance will be pursued by a annealed solution at ~1900°F then submergence in water. 2507 is easily cold worked and has a greater strength/lower ductility than austenitic stainless grades.

Physical Properties:

| Condition | Tensile | Yield | Enlongation | Reduction of Area |

Hardness |

| Annealed | 110 | 80 | 25 | – | 32 HRC Max |

Applications

Valves

Pump and Boat Shafts

Heat Exchangers

Water Desalinization

Power Generation

Chemical

Pulp and Paper

Oil and Gas

Benefits

Very high corrosion resistance

Superior resistance to pitting and cracking in harsh environments

Good weldability and workability

High yield and tensile strength