Special Shape Guide Rail Steel Bar for Elevator

Special Shape Guide Rail Steel Bar for Elevator

The continuous control over the technological processes is conducted on all stages of the production from steel making to final drawing and timely adjustments are carried out if needed.

In order to be labeled as finished, elevator guide rails go through several inspection points, which include stream inspection,sample checks on defectoscopes and manual control before packaging.

All business processes on the enterprise are in line with the international quality standard ISO 900l:2001 and ISO TS 16949,the standard for automotive production and relevant service part organizations.

ELEVATOR SYSTEMS

We have been producing high quality guide rails for elevator systems for over 30 years.

Thanks to this long experience in the manufacture of elevator guide rails, our end products are now highly regarded on the world market. For more than 10 years now, we have also been supplying internationally from our production and order picking location in Hoyerswerda. Our customers particularly appreciate our possibilities of processing, packaging and just-in-time delivery directly to the construction site. In addition to the guide rails, we also produce other components for elevator systems and special profiles for elevator cabins. The guide rails are manufactured according to ISO 7465 and TS 14-11-245-88.

Model:

T45A, T50A, T70B, T75B, T78B, T82B, T89B, T90B, T114B, T127B, TK3, TK3A, TK5, TK5A.

Type

- Machined Elevator Guide Rail

- Cold Drawn Elevator Guide Rail

- Hollow Elevator Guide Rail

- Customized Elevator Guide Rail

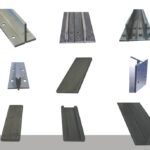

5. Cold drawn elevator guide rail fishplates, machined elevator guide rail fishplates, special thicness fishplates, T section fishplates, forged clips, sliding clamps, sliding clips, T-clips

Reference: ISO7465:2007/(GB/T 22562-2008·

Raw material: E 275 B (ISO 630:1995), corresponding-to Fe 430 B.

Guide rail length: 5000 mm ± 2mm.

Different length according to customers’ requirements

Different guide rails sections & specifications: according to definition with customers.

COLD DRAWN

Cold drawn elevator guide rails are used as counterweight rails or in elevators with relatively low speeds, typically up to 1.6 m/s. VOL-Stahl offers all dimensions of elevator guide rails to ISO 7465, as well as special dimensions such as RO50.9 and RO70.9.

MACHINED

Machined elevator guide rails have a smoother running surface compared to cold-drawn ones and are therefore better suited for heavy-duty and high-speed applications

HIGH QUALITY GUIDE RAILS

Perfect geometry, high surface smoothness and perfect connections – these are the requirements for high-quality guide rails. Key factors for safety in the environment of exceptionally high pressures and speeds are tight tolerances combined with excellent mechanical properties of the material.

Cabin profiles

As a producer of special steel profiles we deliver not only guide rails,but also other cold drawn profiles that are employed in the production of elevators and door elements,in particular.

Packing

Our guide rails are packed in bundles with protective sheathes protecting both ends, each bundle repacked in blue plastic sheeting. We can also pack as per your request.