Hot Rolled Steel Section For Track Shoe

Hot Rolled Steel Section For Track Shoe

The track shoe is one of the main components of the track. The crawler belt is a flexible chain ring driven by the driving wheel, surrounding the driving wheel, the road wheel, the inducer wheel and the supporting wheel , and is composed of a crawler shoe and a crawler pin. Both ends of the track shoe hole , engaged with the drive wheel , the central induce teeth , for tacticity track , and prevent downstream product off the track during turning or driving roll , in contact with the ground on one side with a reinforcing rib slip , to Improve the firmness of the track shoe and the adhesion between the track and the ground. The track pin connects each track shoe to form a track chain link. At this stage , track shoes are widely used in construction machinery, military machinery, agricultural machinery and other fields.

Commonly used track shoes are divided into three types according to the grounding shape, there are single-reinforced, three-reinforced and flat-bottomed, and some of them also use triangular track shoes. Single-reinforced track shoes are mainly used for bulldozers and tractors, because this type of machinery requires the track shoes to have a higher traction capacity when working. However, it is rarely used on excavators. This type of track shoe is only used when the excavator is equipped with a drill frame or requires a large horizontal thrust. A higher traction is required when turning from a child, so a higher crawler bar (ie crawler spur) will squeeze away the soil (or ground) between the crawler bars, thereby affecting the mobility of the excavator.

Track shoe classification

There are many classification methods for track shoes , and they can be divided into different product types according to different classification methods.

- 1.According to different materials , can be employed into the track shoe 23MnB material produced track shoe using 25MnB material produced track shoe using 35MnTiB material produced track shoe using 40Mn2Si material produced track shoe plate materials produced track product type.

- According to the different pitch , the track shoes can be divided into 216 pitch track shoes, 190 pitch track shoes and other product types.

- According to different downstream application fields , crawler shoes can be divided into crawler shoes for bulldozers, crawler shoes for excavators, crawler shoes for tanks, crawler shoes for crawler cranes, and crawler shoes for automobiles.

Track shoe specifications

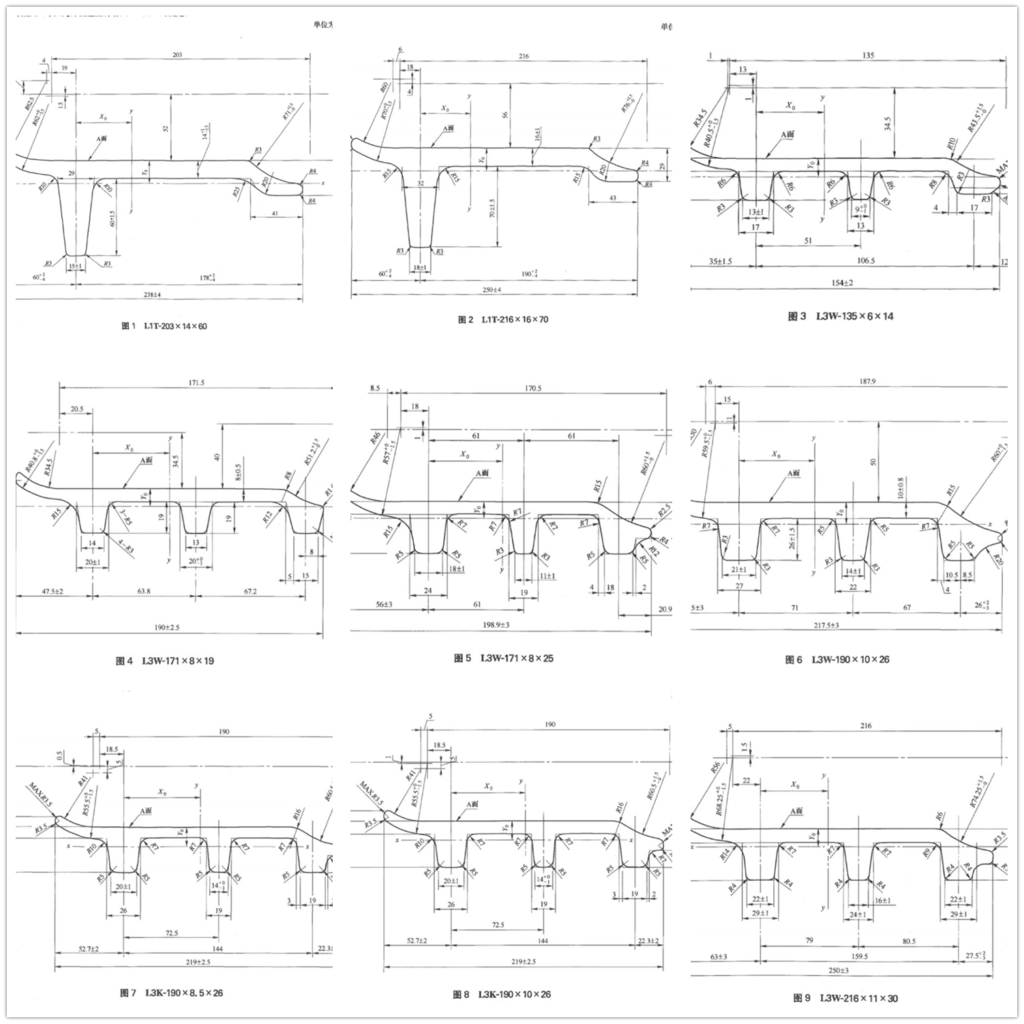

Specifications, cross-sectional area, theoretical weight and cross-sectional characteristics of hot-rolled steel

| specification | Cross-sectional area cm 2 | Theoretical weight kg/m | Sectional characteristics | |||||

| xx | xx | yy | yy | Center of gravity distance /cm | ||||

| Section factor | Moment of inertia | Section factor | Moment of inertia | |||||

| Wx/cm3 | Ix/cm4 | Wy/cm3 | Iy/cm4 | Xo | Yo | |||

| L1T-203X14X60 | 44.70 | 35.09 | 26.56 | 149.10 | 126.44 | 1,696.06 | 4.39 | 1.78 |

| L1T-216X16X70 | 56.15 | 44.08 | 40.74 | 263.53 | 164.50 | 2,375.75 | 4.55 | 2.13 |

| L3W-135X6X14 | 13.89 | 10.90 | 3.09 | 4.11 | 32.66 | 253.41 | 4.26 | 0.67 |

| L3W-171X8X19 | 23.76 | 18.65 | 6.44 | 14.32 | 67.8 | 673.19 | 5.18 | 0.91 |

| L3V-171X8X25 | 29.03 | 22.79 | 12.87 | 26.93 | 82.81 | 850.92 | 4.68 | 1.21 |

| L3W-190X10X26 | 36.72 | 28.83 | 17.97 | 40.61 | 116.05 | 1,293.90 | 5.80 | 1.34 |

| L3K-190X8.5X26 | 33.00 | 25.90 | 14.93 | 33.09 | 110.65 | 1234.94 | 5.89 | 1.23 |

| L3K-190X10X26 | 36.28 | 28.48 | 16.35 | 38.04 | 122.63 | 1,366.37 | 5.87 | 1.27 |

| L3W-216X11X30 | 46.18 | 36.25 | 24.93 | 65.10 | 167.31 | 2,164.05 | 6.63 | 1.49 |

Chemical composition of track shoe

| Grade | Chemical composition (mass fraction) /% | ||||||||

| C | Si | Mn | P | S | Cr | B | Ti | Als | |

| 23MnBM | 0.20 ~ 0.27 | 0.15 〜0.30 | 0. 80 〜1.10 | ≤0. 030 | ≤0. 030 | 0.10 ~ 0.30 | 0. 0005 〜0. 0030 | 0. 010 〜0. 050 | 0. 01 〜0. 07 |

| 25MnB | 0.23 ~ 0.28 | 0. 15 〜0. 30 | 1. 00 〜1. 30 | ≤0. 030 | ≤0. 030 | 0.10 ~ 0.30 | 0. 0005 〜0. 0030 | 0. 010 〜0. 065 | 0. 01 〜0. 06 |

| 30MnTiB | 0.27 ~ 0.34 | 0. 17 〜0.37 | 1.20 ~ 1.50 | ≤0. 030 | ≤0. 030 | ≤0. 30 | 0. 0005 〜0. 0030 | 0. 020 〜0. 060 | 0. 01 〜0. 07 |

| 35MnTiB | 0. 32 〜0.39 | 0.17 ~ 0.37 | 0. 90 〜L 30 | ≤0. 030 | ≤0. 030 | ≤0. 30 | 0.0005 〜0.0030 | 0. 020 〜0.060 | 0. 01 〜0. 07 |

| 40SiMn2 | 0. 37 〜0.44 | 0. 60 〜].00 | 1. 40 ~ 1. 80 | ≤0. 030 | ≤0. 030 | ≤0. 30 | — | — | 0. 01 〜0. 07 |

| 23MnBM is a commonly used grade in the construction machinery industry. This grade can also be expressed as 23MnB according to the general expression method without causing ambiguity . | |||||||||

Straightness

| Curvature per meter | Curvature within 1m from both ends | Total curvature |

| ≤4 | ≤6 | ≤0.4%L |

| Note : L is the total length of section steel. Unit is mm | ||

Track shoe delivery status

The track shoes are delivered in a hot rolled state .

Grain size

The track shoe should be tested grain size , austenite grain size should be no bigger than the level . 6 stage .

Non-metallic inclusions

The track shoe steel should be inspected for non-metallic inclusions, and the A, B, C , and D inclusions should be no more than 2.5 grades .

Surface quality of track shoes

- lThesurface of the track shoe is not allowed to have cracks, folds, scars, bubbles and inclusions , no bumps on the A side , and no delamination on both ends.

- lThe surface of the track shoe is allowed to have local hair lines, pits, scratches, pits and bumps except A The depth or height of the above defects is not allowed to be greater than 1mm . Ears whose height is not more than half of the negative deviation of the side width are allowed on the surface of the short side of the section steel.

- lUnder normal circumstances , for hot-rolled steel for single-tooth track , the two sides of the section are allowed to have folds with a depth of not more than 5mm , and the two sides of the section are allowed to have ears that are not more than half of the negative deviation of the side width and the depth is not more than 1.0 mm rolling.

- lThe surface defects of the track shoes are allowed to be removed along the rolling direction . The cleaning depth is not allowed to be greater than The cleaning place should be smooth and without edges and corners , and the cleaning width should be greater than 5 times the cleaning depth .

- lThe surface defects of the track shoes are not allowed to be welded and filled.

Special requirements

According to the requirements of the buyer and specified in the contract , the track shoe can be subjected to low magnification ( low magnification of steel or low magnification of continuous casting billet ) , decarburization layer, surface hardness, total oxygen of steel, nitrogen content in steel, and end hardening inspection of other projects , its index is determined by mutual agreement.