Heat Resistant Steel

Such steel is generally used in applications where resistance to increased temperatures are critical. The steel is hard wearing and offers a resistance to large variations in temperature. Industrial applications include furnaces, heat exchanges and incinerators where temperatures can reach in excess of 1100°C.

Characteristics include corrosive resistance, creep resistance, oxidation resistance and hydrogen brittleness – all under extremely high temperatures. Our steels are made from nickel and titanium based alloys for outstanding high temperature performance.

Heat Resistant Steel refers to the steel which is capable of resist scaling at temperature above 500°C. The heat resistant steel grades are not exposed to mechanical stress, owing to its oxidized layer which is created throughout the developing process when the steel is exposed to gentle and strong oxidizing conditions at elevated temperatures.

This steel is adherent and its intense oxide layers provides the heat resistance of the material. It is capable of upholding processes when exposed, either continuously or erratically, to operating temperatures which result in metal temperatures in excess of 650°C. The heat resistance of the steel depends on its chromium, silicon and aluminum content.

About Chrome Moly

Chrome Moly is one of our most popular heat resistant steels and is commonly found throughout the oil, gas and petrochemical industries. The combination of chromium (giving the steel excellent corrosion resistance) and Molybdenum (for greater tensile strength and heat resistance), makes this steel an ideal choice for high temperature working environments.

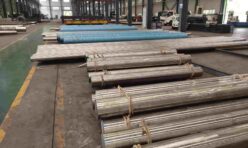

The range of steels offered by Masteel includes plate, sheet, bar, pipe, tube and fittings. Standard and non standard sizes are available from stock, items outside of current stock can be produced rolled to size (utilising allocated rolling programme’s).

Chrome Moly Plate

Chrome Molybdenum steel plate (often referred to in the industry as Chrome Moly) is used for a wide variety of applications particularly in the oil and gas industry, the nuclear industry and fossil fuel power stations.

The molybdenum provides increased strength and higher working temperatures whilst the chromium facilitates excellent corrosion resistance and oxidation.

With such high temperature tensile strength and anti-corrosive properties, our chrome molybdenum is also highly effective in salt water applications. Masteel offers an extensive range of chrome moly steel plate with the following benefits:

- major stockholding

- global shipping

- variety of plate widths

- extensive range of thicknesses

- quick turnaround

- accurate ‘in-house’ cutting and profiling service

- high quality steel from major European steel mills

For further information about our grades of chrome molybdenum steel plate please refer to the specifications below:

Specifications & Grades:

- ASTM A387

- ASME SA387

- EN 10028

- BS 1501

Heat resistant steels can be classified on the basis of their microstructure as follows :

| Classification of heat resistant steel | The most important steel grades | Properties | Fields of application |

| Ferritic, ferritic-martensitic, marensitic heat-resistant steel | Wnr. 1.4724 Wnr. 1.4742 Wnr. 1.4762 | ・ These steel grades display relatively low toughness under impact loading ・ Wnr. 1.4724 (H-12): heat resistant up to 950°C ・ Wnr. 1.4762 (H-14): heat resistant up to 1200°C | • Wnr. 1.4724 (H-12): industrial furnaces, steam boilers, boxes, tubes, hangers, recuperators, etc • Wnr. 1.4762 (H-14): production of industrial furnaces, parts of steam boilers, pyrometer protection tubes |

| Austenitic heat-resistant steel | Wnr. 1.4828 Wnr. 1.4841 Wnr. 1.4845 | • Austenitic heat-resistant steels have much higher elevated temperature and creep strength than ferritic steels • Wnr. 1.4828 (H-8): not susceptible to intergranular corrosion, offers a low resistance to corrosion to oxidising and reducing sulphur bearing gases. Heat resistant up to 1000°C • Wnr. 1.4845 (H-9): heat resistant up to 1050°C • Wnr. 1.4841 (H-10): heat resistant up to 1150°C • Wnr. 1.4878: has good mechanical properties, heat resistant up to 850°C | • Wnr. 1.4828: exhaust systems, etc • Wnr. 1.4845: manufacture of components for chemical and petroleum industries, gas lines, fuel lines, fire boxes, heater resistors • Wnr. 1.4841: components that are exposed to high mechanical strength, industrial furnaces, waste incineration plants, thermal treatment plants, petrochemical industry, etc • Wnr. 1.4878: heat exchangers, boilers in chemical and petrochemical plant, etc |