4330V MOD Quenched and Tempered Steel

4330V MOD Quenched and Tempered Steel

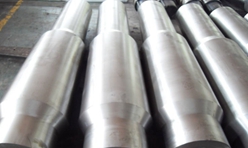

1. 4330V Introduction

4330V alloy steel bar has hardenability that is improved with the addition of vanadium. In the heat treated condition 4330V has good fatigue strength and toughness. Machining is best when annealed, normalized and tempered. It also may be welded with traditional methods.

Back to Top

2. 4330V Applications

Drilling Equipment

Aircraft Landing Gear

Tool Holding Components

High Impact Machine Parts

Back to Top

3.Quality Standard

ASTM A29 Standard Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General

API 7 Specification for Rotary Drill Stem Elements.

Back to Top

4.Related Specifications

- AMS 6427

- SAE AMS 4330M

- ASTM A646

Back to Top

5. 4330V Chemical Composition(%)

| C | Mn | Si | P | S | Cr | Ni | Mo | V |

|---|---|---|---|---|---|---|---|---|

| 0.30-0.34 | 0.75-1.00 | 0.15-0.35 | 0.035 max | 0.035 max | 0.75-1.00 | 1.65-2.00 | 0.40-0.50 | 0.05-0.10 |

Back to Top

6.Mechanical Property Requirements

| Tensile Strength Rm (KSI) | Yield Strength R2 (KSI) | Elongation(%) | Reduction Ration (%) | Izod Impact (J) | Hardness (BHN) |

|---|---|---|---|---|---|

| 160 min | 160 min | 15 min | 321-375 |

Back to Top

7.HEAT TREATMENT

Heat treatment temperatures, including rate of heating, cooling and soaking times will vary due to factors such as the shape and size of each steel component. Other considerations during the heat treatment process include the type of furnace, quenching medium and work piece transfer facilities.

Annealing:Heat the steel slowly to 820-860°C and allow enough time for the steel to be thoroughly heated. Cool slowly in the furnace to 580°C followed by air cooling.

Stress Relieving: When parts are heavily machined, ground or otherwise subject to cold work, stress relieving will be beneficial prior to hardening.

Hardening: 4330V steel is usually supplied ready heat treated to 35-39 HRc. If further heat treatment is required annealed 4330V should be heated slowly to 840-875°C and after adequate soaking at this temperature quench in oil. Temper as soon as the tools reach room temperature.

Tempering: Heat carefully to a suitable temperature selected by reference to a tempering chart or table, soak at the temperature for 2 hours per 25mm of ruling section, then allow to cool in air.

Back to Top

8.WORKABLITY

Forging: Preheat the steel carefully, then raise the temperature to 1070-1230°C for forging. Do not forge below 850°C. 4330V has good forging characteristics but care must be taken when cooling the steel due to its susceptibility to cracking. Cooling in ash or lime after forging is recommended.

Machining: Normalize and Temper at 1250°F(677°C) maximum prior to rough machine. This steel may also be machined at maximum strength, but machining must then be followed with a stress relieving at approximately 400°F(204°C).

Weldability: The steel has good welding characteristics and can be welded by resistance flash welding.

Back to Top

9.Mill′s test certificate

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Back to Top