33NiCrMoV14-5 1.6956 Alloy Special Steels

33NiCrMoV14-5 1.6956 Alloy Special Steels

1. 1.6956 Description and Application

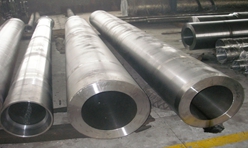

EN 1.6956 steel is an alloy steel formulated for primary forming into wrought products. Cited properties are appropriate for the quenched and tempered condition. 1.6956 is the EN numeric designation for this material. 33NiCrMoV14-5 is the EN chemical designation. 33NiCrMoV14-5 1.6956 Alloy Special Steels are widely used in the filed of ship, vehicle, airplane, guided missile, weapons, railway, bridges, pressure vessel, machine tools, mechanical components with a bigger sectional size and so on.

Back to Top

2.All Grades Comparison

Back to Top

3.Quality Standard

EN 10250 Open steel die forgings for general engineering purposes. Alloy special steels

Back to Top

4. 1.6956 Chemical Composition(%)

| C | Mn | Si | P | S | Cr | Ni | Mo | V |

|---|---|---|---|---|---|---|---|---|

| 0.28-0.38 | 0.15-0.40 | 0.40 max | 0.035 max | 0.035 max | 1.00-1.70 | 2.90-3.80 | 0.30-0.60 | 0.08-0.25 |

Back to Top

5.Mechanical Properties(T=20°C if not differently stated)

| Process | Diameter(mm) | Tensile Strength Rm (Mpa) | Yield Strength Rp0.2 (Mpa) | Elongation A5 (%) (l) | Elongation A5 (%) (tr) | Impact Value Kv (J) Room Temperature (l) | Impact Value Kv (J) Room Temperature (tr) |

|---|---|---|---|---|---|---|---|

| QUENCHED AND TEMPERED | 160 max | 1100 min | 980 min | 10 min | 7 min | 28 min | 17 min |

| QUENCHED AND TEMPERED | 160-330 | 1000 min | 820 min | 12 min | 8 min | 48 min | 27 min |

| QUENCHED AND TEMPERED | 330-660 | 950 min | 780 min | 12 min | 8 min | 48 min | 27 min |

Back to Top

6. 1.6956 HEAT TREATMENT:

- Hardening: Harden from a temperature of 820-890oC followed by oil or quenching.

- Tempering: 550-650oC

Back to Top

7.Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Back to Top