Monel 404 UNS N04404 DIN W. Nr. 2.4867 Alloy

Monel 404 UNS N04404 DIN W. Nr. 2.4867

With over 35 years of industry expertise, Fushun has the industry knowledge and resources to find you the metal products that you need for your specific industry applications. We are in stock and ready to quickly deliver hard-to-find metals. Our ISO 9001-certified metal supply is one of the most comprehensive selections on the market. We provide timely customer support and quick delivery on all quantities of our in stock products.

Contact us for more information regarding our nickel alloy manufacturing and distribution options. Fushun is your trusted nickel alloy supplier for all types of Nickel alloy material.

Features:

Monel 404 has low magnetic permeability and low Curie temperature. Because its low magnetic permeability is not significantly affected by processing and fabrication, it is particularly suitable for electronic parts.

Back to Top

Applications

The MONEL 404 alloy is used in the following applications:

Capsules for transistors

Ceramic to metal sealing

Back to Top

Chemical composition

| % | Ni | Cu | Fe | C | Mn | Si | S | Al |

| max | 52-57.0 | balance | 0.50 | 0.15 | 0.10 | 0.10 | 0.024 | 0.05 |

Back to Top

PHYSICAL PROPERTIES

Density: 0.322 lbs/in3, 8.91 g/cm3

Electrical Resistivity: ohm-cir mil/ft (microhm-m)

At 70 °F (21 °C): 294 (0.498)

Specific Heat: Btu/lb-°F (J/g-°C)

At 70 °F (21 °C): 0.0989 (0.414)

Thermal Conductivity: BTU/hr/ft2/ft/°F (W/m-°C)

At 70 °F (21 °C)-133 (21)

Mean Coefficient of Thermal Expansion: µin/in-°F,(µm/m°C)

70 – 200 °F (21 – 93 °C) 7.39 (13.3)

70 – 572 °F (21 – 300 °C) 8.50 (15.3)

70 – 1000 °F (21 – 539 °C) 9.22 (16.6)

70 – 1500 °F (21 – 816 °C) 9.78 (17.6)

Modulus of Elasticity: ksi (MPa) in Tension

24.5 X 103 (169 X 103)

Magnetic Permeability, H = 200 Oersteds: Annealed 1.0017 max

Melting Point: 2370 °F (1300 °C)

Back to Top

Machinability

Conventional machining techniques used on iron alloys may be used for this alloy.

Back to Top

Welding

Alloy 404 is can be welded using common welding techniques.

Back to Top

Hot working

This alloy cannot be hot worked.

Back to Top

Forging

Alloy 404 can be forged.

Back to Top

Cold working

Cold working may be done using standard tooling and soft die materials for better finish.

Back to Top

Annealing

MONEL 404 alloy should be annealed at 760°C (1400°F) for one hour.

Back to Top

Quality & Testing

Fushun supply Certification with all shipments, containing full chemical analysis and also mechanical test results if requested.

All incoming material is visually inspected and PMI (Positive Material Identification) tested before processing begins and all our production material is checked during each stage of processing.

All incoming orders are produced to the individual customer specification, some of which may involve processing sample batches for testing prior to full production.

Final Inspection carried out on all finished material to include:

Visual inspection

Dimensional checks

PMI (Positive Material Identification)

Mechanical tests

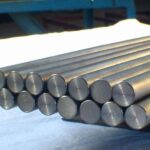

Nickel Alloy Material Available Formats

Fushun offers pure Nickel alloy materials in a variety of forms, including:

Seamless & welded pipe

Seamless & welded tube

Bar

Wire

Sheet

Plate

Forgings

Pipe fittings

Flanges

Weld Rod

Nickel Alloy Supply Quantities for Single Items or Full Bills

At Fushun, we can supply single items or full bills of nickel alloy materials for most any project. No inquiry is too small. We offer quick responses to customer inquiries and specialize in the rapid delivery of both large and small quantities of nickel alloy products.

Contact Fushun for Nickel Alloy Materials Today

Contact us for more information regarding our nickel alloy material options, or request a quote for further pricing details today. Fushun is your trusted nickel alloy supplier and manufacturer of premium nickel alloy materials.