Nickel 200 Alloy

With over 35 years of industry expertise, Fushun has the industry knowledge and resources to find you the metal products that you need for your specific industry applications. We are in stock and ready to quickly deliver hard-to-find metals. Our ISO 9001-certified metal supply is one of the most comprehensive selections on the market. We provide timely customer support and quick delivery on all quantities of our in stock products.

Contact us for more information regarding our nickel alloy manufacturing and distribution options. Fushun is your trusted nickel alloy supplier for all types of Nickel alloy material.

NICKEL 200 DESCRIPTION

Nickel 200 is a solid solution strengthened, commercially pure wrought materials with excellent mechanical properties and resistance to corrosion. It also has exceptional resistance to caustic alkalis at different concentrations and temperatures. However, the corrosion resistance is better in de-aerated acid. The alloy has low gas content and vapor pressure, and high thermal and electrical conductivities. Nickel 200 (UNS N02200/W.Nr. 2.4060) is commercially pure (99.6%) wrought nickel. It has good mechanical properties and excellent resistance to many corrosive environments. Other useful features of the alloy are its magnetic and magnetostrictive properties, high thermal and electrical conductivities, low gas content and low vapor pressure. The corrosion resistance of Nickel 200 makes it particularly useful for maintaining product purity in the handling of foods, synthetic fibers, and caustic alkalies; and also in structural applications where resistance to corrosion is a prime consideration. Other applications include chemical shipping drums, electrical and electronic parts, aerospace and missile components.

What are the characteristics of Nickel 200/201?

Highly resistant to various reducing chemicals

Excellent resistance to caustic alkalies

High electrical conductivity

Excellent corrosion resistance to distilled and natural waters

Resistance to neutral and alkaline salt solutions

Excellent resistance to dry fluorine

Widely used to handle caustic soda

Good thermal, electrical and magnetostrictive properties

Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations

Nickel 200/201 ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet / Plate | Bar | Fitting |

| B161 | B622 | B161 | B622 | B162 | B160 | B163 |

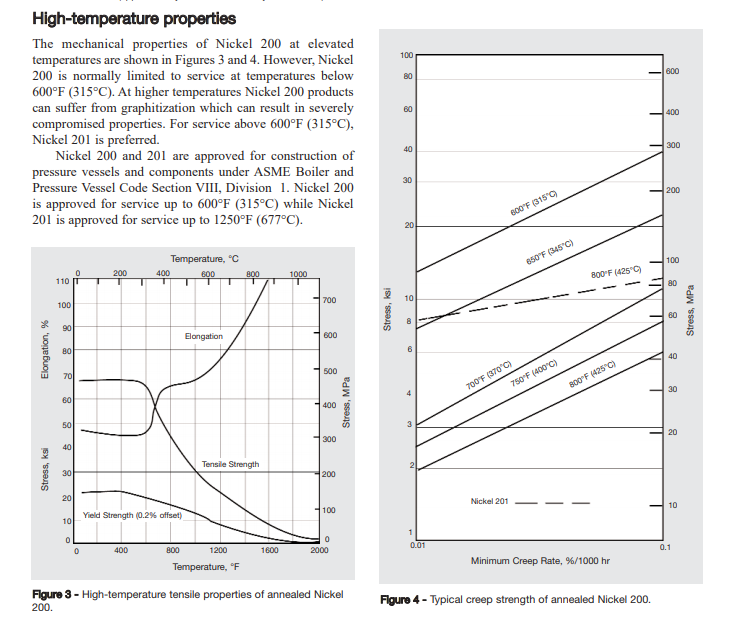

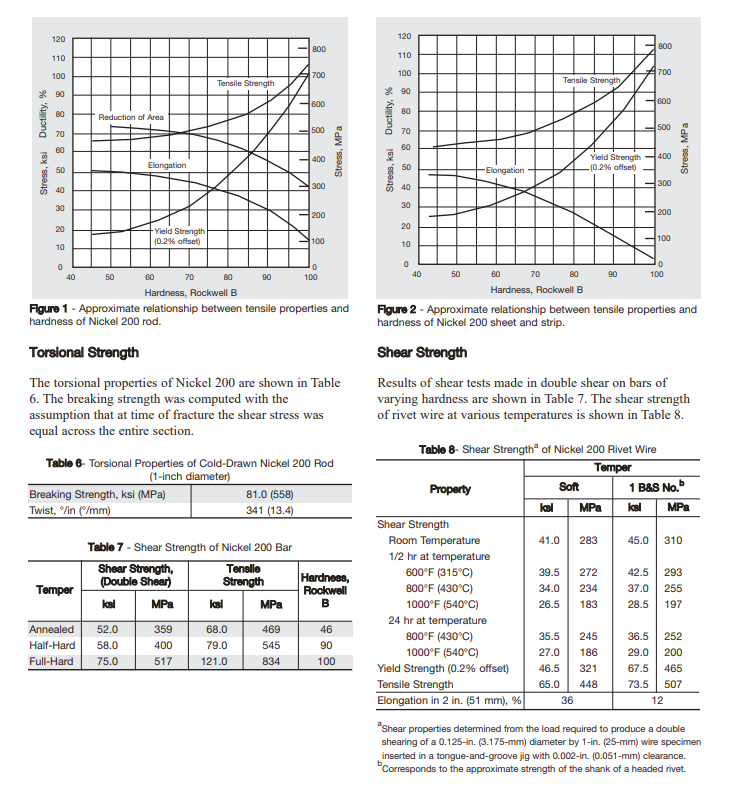

Mechanical Properties

Room Temperature properties of Various Products

| Product Form | Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

| Rod & Bar | Hot Finished | 60-85 | 15-45 | 55-35 | 45-80 |

| Rod & Bar | Cold Drawn / Annealed or Hot-Finished / Annealed | 55-75 | 15-30 | 55-40 | 45-70 |

| Plate | Hot-Rolled / Annealed | 55-80 | 15-40 | 60-40 | 45-75 |

| Sheet | Annealed | 55-75 | 15-30 | 55-40 | 70 max |

| Tube & Pipe | Seamless Annealed | 55-75 | 12-30 | 60-40 | 70 max |

| Form | ASTM |

| Rod and bar | B 160 |

| Plate, sheet and strip | B 162, B 906 |

| Seamless pipe and tube | B 161, B 829 |

| Welded pipe | B 725, B 775 |

| Welded tube | B 730, B 751 |

| Welding fitting | B 366 |

| Forging | B 564 |

APPLICATIONS

Electronic components where going maybe required

Lead wires

Battery components

Transducers

Sparking electrodes

Heat exchangers

Bands and tags

Chemical composition:

| Grade | Chemical Component % | ||||||

| Ni | Fe | Cu | C | Mn | S | Si | |

| Nickel 200 | Min 99.0 | Max 0.4 | Max 0.25 | Max 0.15 | Max 0.35 | Max 0.01 | Max 0.35 |

PHYSICAL PROPERTIES

Density, 0.321 lbs/in³, 8.89 g/cm³

Specific Heat: BTU/lb/°F (J/kg•K):

32-212°F (0-100°C): 0.12 (456)

Thermal Conductivity, BTU/hr/ft²/ft/°F (W/m•K)

At 212ºF (100ºC): 38.8(67.1)

At 400°F (204°C): 35.4(61.3)

At 600ºF (316ºC): 36.5(56.3)

Mean Coefficient of Thermal Expansion: in/in/°F (μm/m•K)

80-200°F (27- 93°C): 7.4 x 10 (13.3)

80-400°F (27-204°C): 7.7x 10 (13.9)

80-600°F (27-316°C): 8.0x 10 (14.4)

Modulus of Elasticity, KSI (MPa)

30.0x 10³ (207 x 10³)

Melting Range: 2615-2535°F (1435-1445°C)

MECHANICAL PROPERTIES AT ROOM TEMPERATURE

PROPERTIES: ANNEALED

Ultimate Tensile Strength: 55 KSI min (380 MPa min)

Yield Strength (0.2% offset): 15 KSI min (100 MPa min)

Elongation:

35% min: gauges ≤ 0.0035 inches

40% min: gauges > 0.0035 inches

Hardness:

HV 117 max: gauges ≤ 0.010 inches

Rb 66 max: gauges > 0.010 inches

PROPERTIES: TEMPERED

Nickel 200 can be cold rolled to achieve the temper properties required by specific customers and/or manufacturing requirements. Contact Ulbrich Wire for details.

Physical Properties

The following table shows the physical properties of Nickel 200 alloy.

| Properties | Metric | Imperial |

| Density | 8.89 g/cm3 | 0.321 lb/in3 |

| Melting point | 1435-1446°C | 2615-2635°F |

Thermal Properties

The thermal properties of Nickel 200 alloy are given in the following table

| Properties | Metric | Imperial |

| Thermal expansion co-efficient (@20-100°C/68-212°F) | 13.3 µm/m°C | 7.39 µin/in°F |

| Thermal conductivity | 70.2 W/mK | 487 BTU.in/hrft².°F |

Fabrication and Heat Treatment

Nickel 200 alloy can be shaped through all hot working and cold working practices. The alloy can be hot worked between 649°C (1200°F) and 1232°C (2250°F), with heavy forming carried out at temperatures above 871°C (1600°F). Annealing is performed at temperature between 704°C (1300°F) and 871°C (1600°F).

Other Designations

Other designations that are equivalent to nickel 200 alloy include the following:

ASME SB-160 – SB-163

DIN 17740

DIN 17750-17754

BS 3072-3076

ASTM B 160 – B 163

ASTM B 725

ASTM B 730

STANDARD WIRE FINISHES

Extra Clean: Extra clean is also referred to as “bright annealed” or “bright annealed and cold rolled”

Grease (round wire only): Drawn in a heavy grease produces an “Ultra bright” finish for decorative applications

Soap (round wire only): Soap is used as a lubricant in the drawing process and is not removed. It acts as a lubricant during customer part forming operation.

A soap finish is available in tempered products.

Plated: Many plating options are available.

Quality & Testing

Fushun supply Certification with all shipments, containing full chemical analysis and also mechanical test results if requested.

All incoming material is visually inspected and PMI (Positive Material Identification) tested before processing begins and all our production material is checked during each stage of processing.

All incoming orders are produced to the individual customer specification, some of which may involve processing sample batches for testing prior to full production.

Final Inspection carried out on all finished material to include:

Visual inspection

Dimensional checks

PMI (Positive Material Identification)

Mechanical tests

Nickel Alloy Material Available Formats

Fushun offers pure Nickel alloy materials in a variety of forms, including:

Seamless & welded pipe

Seamless & welded tube

Bar

Wire

Sheet

Plate

Forgings

Pipe fittings

Flanges

Weld Rod

Nickel Alloy Supply Quantities for Single Items or Full Bills

At Fushun, we can supply single items or full bills of nickel alloy materials for most any project. No inquiry is too small. We offer quick responses to customer inquiries and specialize in the rapid delivery of both large and small quantities of nickel alloy products.

Contact Fushun for Nickel Alloy Materials Today

Contact us for more information regarding our nickel alloy material options, or request a quote for further pricing details today. Fushun is your trusted nickel alloy supplier and manufacturer of premium nickel alloy materials.