1.2358 / X60CrMoV18-5 Cold Work Tool Steel

1.2358 _ X60CrMoV18-5 Cold Work Tool Steel

Chrome-molybdenum-vanadium steel is characterized by high toughness and good resistance to the wear. Further the steel has good hardenability and good dimensional stability after hardening and tempering. The steel can also be well welded and well polished. The toughness of quality 1.2358 reaches higher values than by other steels for cold work (1.2842, 1.2363, 1.2080, 1.2379, 1.2436). An excellent combination of toughness and resistance to the wear enables the usage of quality 1.2358 also for different pressing and injection applications during plastics processing.

Applications

For cold work and for molds for plastics. In case of using for cold work we can talk mainly about these applications: cutting and mechanical working (also materials of bigger thicknesses), deep drawing, punching, rolling, production of shear blades, more complicated tools for cold work. In the area of molds for plastics the steel can be used e.g. for molds for large series, molds for plastics with additives, tools for plastics stamping etc.

Equivalent

- Standards: X60CrMoV18-5

- DIN: 2358

Chemical composition (typical analysis in %)

| Standard | Steel Grade | |||||||

| Chemical composition % | ||||||||

| C: | Mn: | Si: | P: | S: | Cr: | Mo: | V: | |

| DIN/EN | 1.2358 – 60CrMoV18-5 | |||||||

| 0.58 – 0.62 | 0.7 – 0.9 | 0.2 – 0.5 | <0.03 | <0.03 | 4.3 – 4.7 | 0.4 – 0.6 | 0.2 – 0.3 | |

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

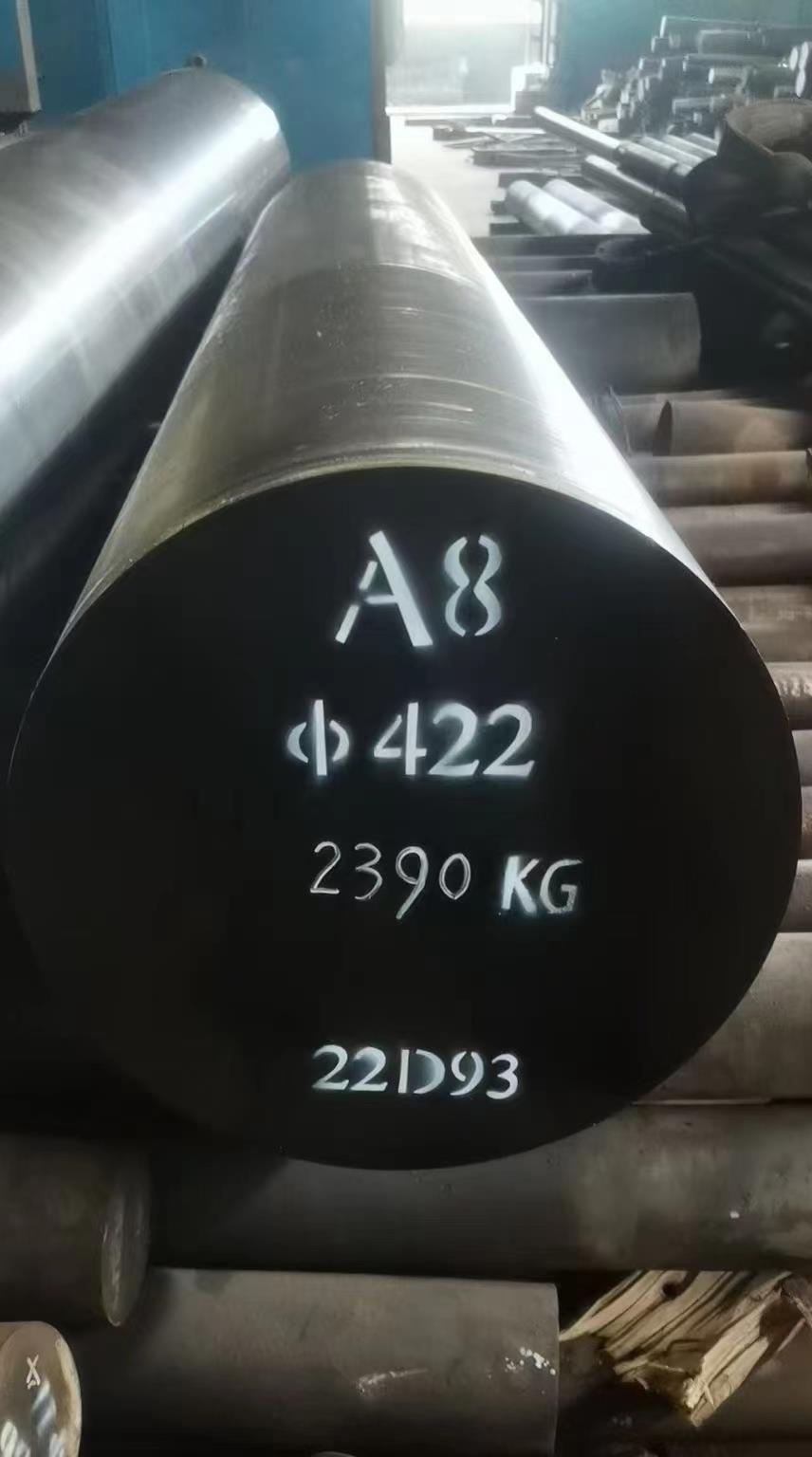

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Suface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

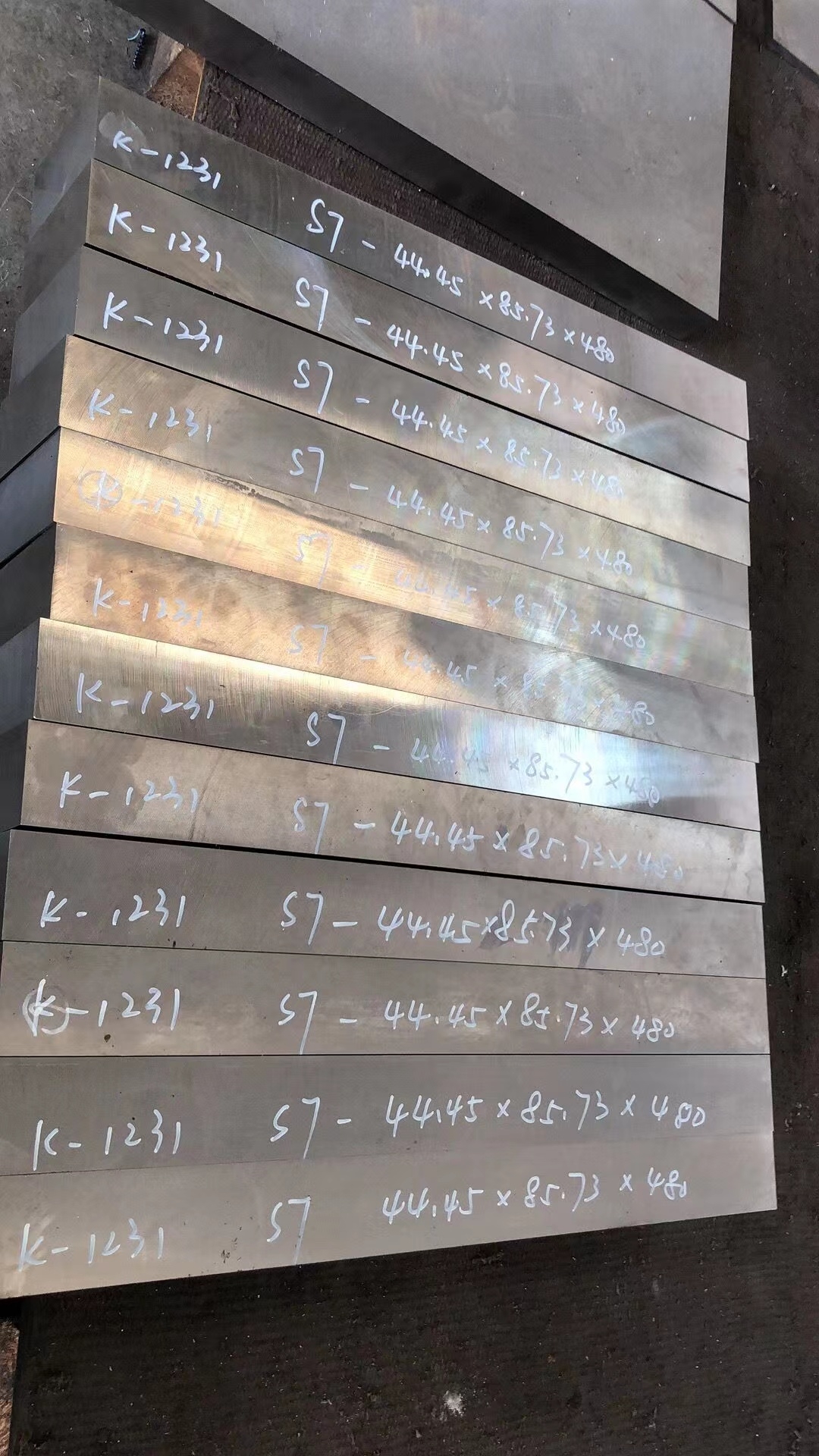

Size range

Diameter (mm)6 – 500 Thickness (mm)6 – 400 Width (mm)Max 810

Delivery condition

Soft annealed to max. 240 HB

Mechanical properties of 60CrMoV18-5, 1.2358

- Hardness in annealed condition +A: <235HB

- Hardness after hardening and tempering at temperature:

200C = 58HRC

300C = 56HRC

350C = 55HRC

500C = 53HRC

550C = 50HRC

- Thermal conductivity 200/400C = 27/13 W*m*K

- Thermal capacity, cp 20/200/400C = 455/525/608 J*Kg*K

Heat treatment – processes and temperatures:

- Softening annealing at a temperature of 820 – 860C

- Stress relief annealing at a temperature of 600 – 650C

- Hardening at a temperature of 950-970C with cooling in oil or salt bath

- Tempering at temperature of >180C

Suitability

Steel W. Nr. 1.2358 can be used both for cold work and for molds for plastics. In case of using for cold work we can talk mainly about these applications: cutting and mechanical working (also materials of bigger thicknesses), deep drawing, punching, rolling, production of shear blades, more complicated tools for cold work. In the area of molds for plastics the steel can be used e.g. for molds for large series, molds for plastics with additives, tools for plastics stamping etc.