1.2601 X165CrMoV12 Cold Work Tool Steel

1.2601 X165CrMoV12 Cold Work Tool Steel

X165CrMoV12 1.2601 is a German Cold work tool alloy steel material grade.it is shock resisting steel. it belong to DIN 17350 standard. Digital Grade material number 1.2601. Metal Steel Grade W-Nr X165CrMoV12 It is a die steel, use in extrusion moulds, Hot Cast moulds. like aluminium production, Aluminium cutting mold.

Applications

Cutting tools, stamping, woodworking, drawing, deep drawing and pressing tools, cold working

rolls , measuring tools .

Material equivalent of DIN X165CrMoV12 | 1.2601 steel

| Germany | Italy | Sweden | Spain |

| DIN,WNr | UNI | SS | UNE |

| X165CrMoV12 | 1.2601 | X165CRMOW12KU | 2310 | X160CRMOV12 |

Chemical composition (wt.%) of 1.2601

| C | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Mo | Other |

| 1.55-1.75 | 0.25-0.40 | 0.20-0.40 | 0.030 | 0.030 | 11.0-12.0 | 0.50-0.70 | V 0.10-0.50 W 0.40-0.60 |

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

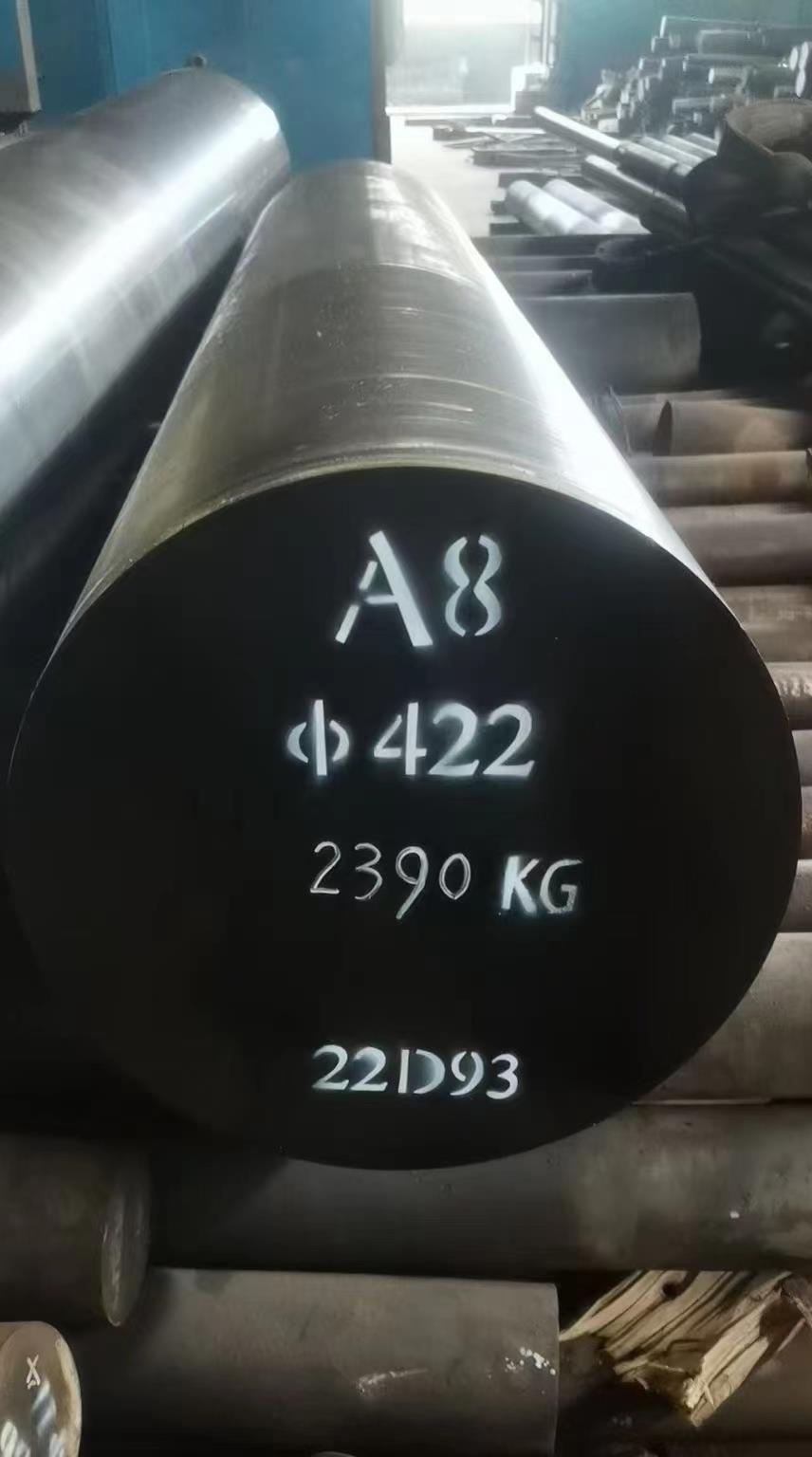

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

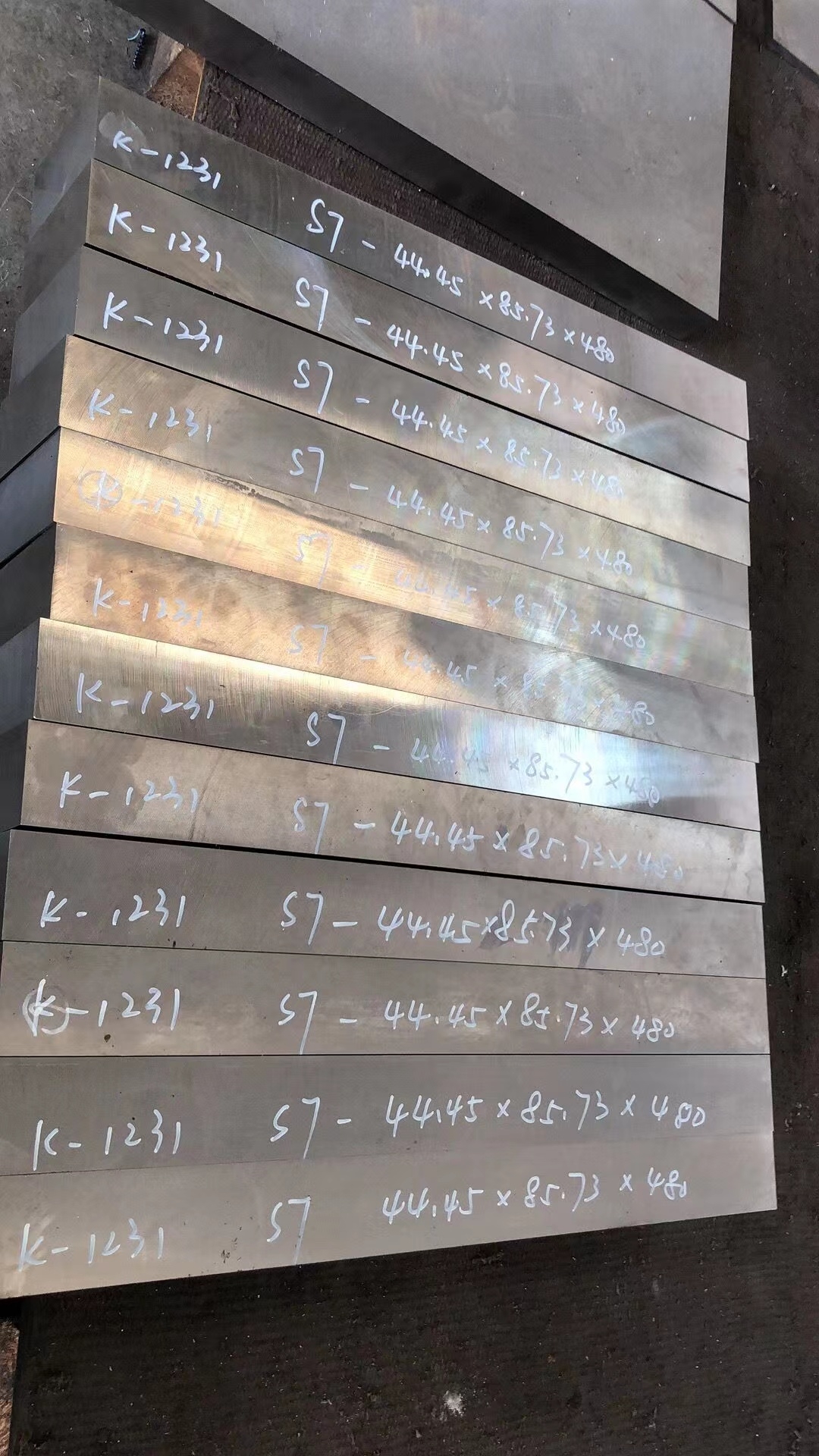

Suface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

Mechanical Properties of 1.2601

| Rp0.2 (MPa) | Rm (MPa) | Impact KV (J) | Elongation A (%) | A Z (%) | Delivery | Hardness HB |

| 641 (≥) | 662 (≥) | 23 | 14 | 31 | Solution & Aging, Ann, Ausaging, Q+T | 142 |

Heat treatment of X165CrMoV12 | 1.2601 Cold work tool steel

Annealing: Annealing temperature/℃: 800~830; After the annealing, degree of hardness ≤HBS: 255

Quenching: Hardening temperature/℃: 980~1010, Quenching in oil or air

Tempering: Commonly used drawing temperature/℃: 180~250; After tempering hardness HRC | 100 ℃ : 63; After tempering hardness HRC | 200 ℃ : 61; After tempering hardness HRC | 300 ℃ : 60 ; After tempering hardness HRC | 400 ℃ : 58

Normalizing:at Normalizing temperature, then cool in furnace