1.2885 X32CrMoCoV3-3-3 H10A Hot Working Tool Steel

1.2885 X32CrMoCoV3-3-3 H10A Hot Working Tool Steel

X32CrMoCoV3-3-3 1.2885 Alloy tool steel with high hardenability, high resistance to tempering, load and high hardness at elevated temperatures. The grade is distinguished by high content of Cobalt in its chemical composition.

Applications

Hot pressing tools exposed to severe stresses in contact with the die insert-mandrels,stamps, punching tools,dies,etc.

Designation by Standards

Steel No. :1.2885

DIN EN :X32CrMoCoV3-3-3

AISI :H10A

Chemical composition (wt.%)

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Mo(%) | V(%) | Co(%) |

| 0.28-0.35 | 0.10-0.40 | 0.15-0.45 | Max 0.030 | Max 0.030 | 2.70-3.20 | 2.60-3.00 | 0.40-0.70 | 9.50-10.5 |

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

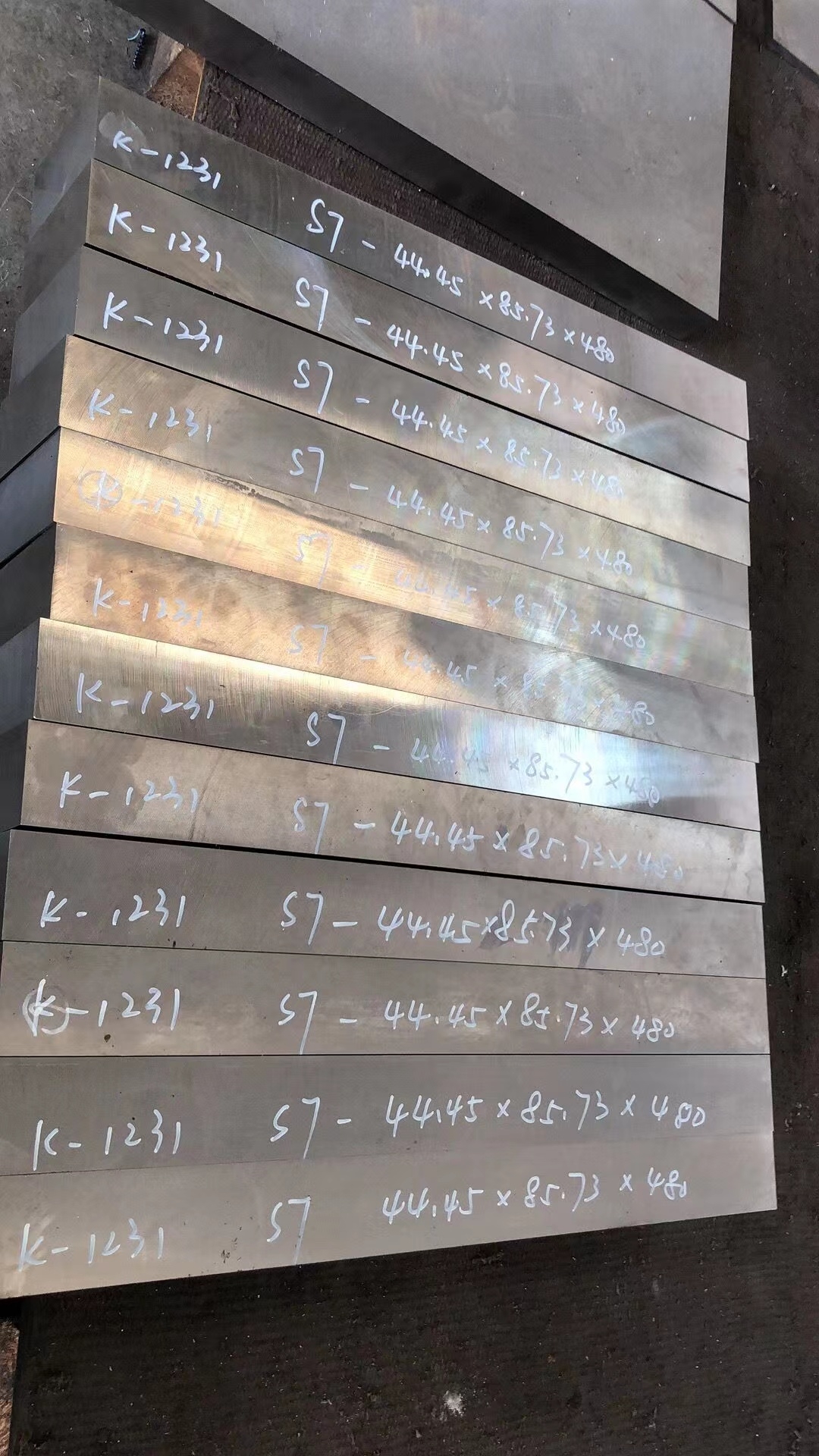

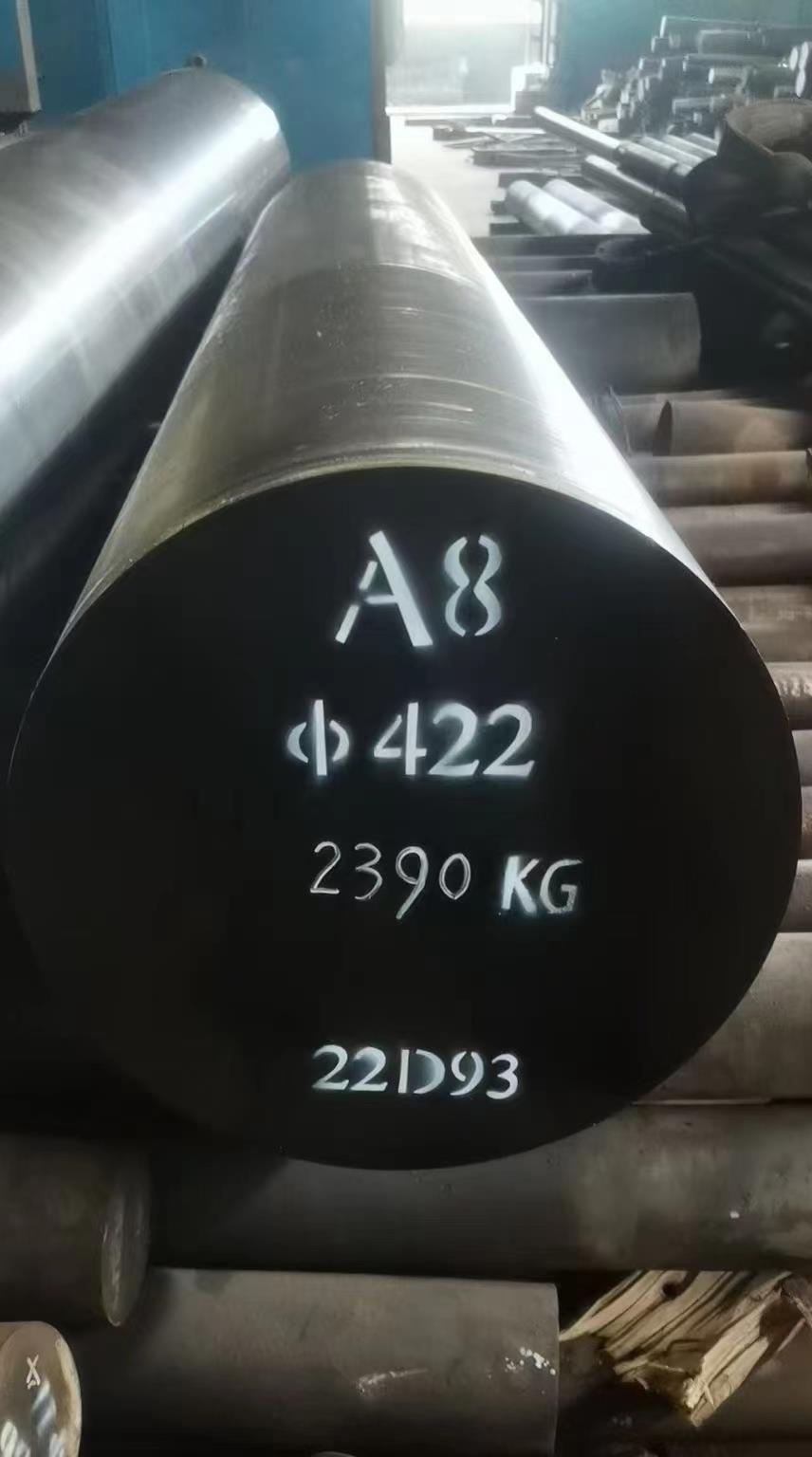

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Suface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

Mechanical properties of 1.2885, X32CrMoCoV3-3-3

Hardness in softening annealed condition <241 HB

Hardness after hardening 53.5 HRC

Hardness after tempering at temperature:

- 300C = 51.5 HRC

- 350C = 51.5 HRC

- 400C = 52.0 HRC

- 450C = 52.5 HRC

- 500C = 53.0 HRC

- 550C = 53.5 HRC

- 600C = 51.5 HRC

Heat treatment – processes and temperatures:

Softening annealing at 740 – 770C with cooling in furnace

Relief annealing at a temperature of 600 – 700C with cooling in furnace

Nitriding at a temperature of 470 – 550C

Hardening at a temperature of 1020 – 1040C with cooling in oil

Tempering at a temperature of 500 – 600C