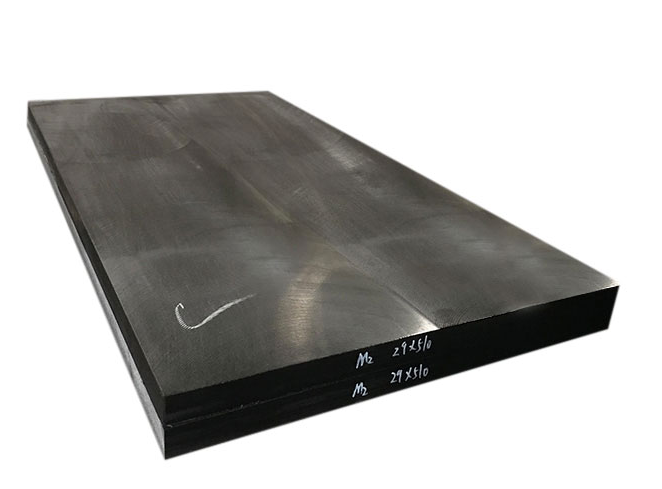

SKH52 1.3350 HS6-6-2 T11313 M3.1 High Speed Tool Steel

SKH52 1.3350 HS6-6-2 T11313 M3.1 High Speed Tool Steel

The high quality 1.3350 JIS SKH52 material is one of the more steel grades we supply, W-phase system high-speed tool steel. SKH52 is our main production grade, which has been approved by customers in many countries since its initial production, including our SKH52 round bars, flat bar, forgings, wires, strips, sheets & Plates, as well as a variety of profiles, professional high precision auto-lathe processing manufacturer of clinching fasteners, axes, standoffs, screws, studs, nuts, bolt, OEM parts and special shaped turning partsthe state of delivery includes quenched and tempered, annealed, machined semi-finished products, we also have strict management of the packaging, to avoid material damage from transportation. We are the best supplier of SKH52 materials, and we are willing to develop together with customers from all over the world.

Equivalent grades of steel HS6-6-2 (1.3350)

| EU EN | Japan JIS | DIN | UNS | ASTM |

| HS6-6-2 | SKH52 | 1.3350 | T11313 | M3.1 |

Chemical composition % of steel HS6-6-2 (1.3350): EN 4957-2000

| C | Si | Mn | P | S | Cr | Mo | W | V |

| 1 – 1.1 | max 0.45 | max 0.4 | max 0.03 | max 0.03 | 3.8 – 4.5 | 5.5 – 6.5 | 5.9 – 6.7 | 2.3 – 2.6 |

Mechanical Properties

| Rp0.2 (MPa) | Rm (MPa) | Impact KV (J) | Elongation A (%) | A Z (%) | Delivery | Hardness HB |

| 136 (≥) | 616 (≥) | 24 | 43 | 32 | Solution & Aging, Ann, Ausaging, Q+T | 331 |

Application of JIS High Speed Tool Steel SKH52 material Grade number

Because of high speed tool steel SKH52 is grinding performance is good, so can be used to manufacture all kinds of complex high precision cutting tool.

Typical Application like Scraper, rolling cutter, iron knives, drill bits, etc

Forging of Tool Steel HSS JIS SKH52

982-1093°C, heat thoroughly, then start forging. slowly cool in furnace.

Annealling of SKH52 Steel JIS HSS tool material

Heat to 871°C, soak thoroughly. then cool slowly in heat treatment furnace

Stress Relieving of JIS SKH52 High Speed Tool Steel

Heat slowly the SKH52 Steel component to 600-650°C and soak well (about two hours) , Then Cool slowly in the furnace.

Tempering of High Speed Tool Steel JIS SKH52 steel grade

Tempered SKH52 Tool Steel for three times at 515-593°C, then cool slowly at furnace. Typical Tempering as below table:

Temperature [°C] 515 550 600

Hardness [HRc] 67 69 63

Hardening of SKH52 Tool Steel HSS Material

Hardening SKH52 Steel Tool component at 1160-1180°C in salt, or 1180-1190°C in atmosphere or vacuum furnaces.

Quenching of SKH52 Tool Steel HSS

Quenching SKH52 tool steel at 538°C, Then Cool it in air.

Final Grinding of JIS SKH52 Tool Steel

For get high precision and smooth surface, the grinding the SKH52 steel material is necessary. choose correct wheel for grinding SKH52. If dry grinding, the soft wheel is advice.

Quality Assured and Certification of SKH 52 steel

Quality control by our ISO 9001:2008 quality system. All steel material MTC certification is supplied follow the orders.