1.2162 21MnCr5 20ХГ Cold Work Tool Steel

1.2162 21MnCr5 20ХГ Cold Work Tool Steel

Grade : 21MnCr5 Number: 1.2162

Classification

Alloy cold-work tool steel

Standard:

EN ISO 4957: 2000 Tool steels

Characteristics

Manganese-chrome steel for case-hardening with the middle hardenability, with the hardness of case-hardened layer and with the high hardness in the core. Further the steel is characterized by a good ductility at the heat, good workability in the annealed state and it is easy to polish.

APPLICATION:

machine parts and moulding plates with a high surface hardness;

synthetic resin press moulds for the processing of thermoplastics and thermosetting plastics.

Suitability

For small and middle-size cemented molds for mechanical working of plastic materials and rubber with the demand on higher hardness in the core.

Chemical composition%of the ladle analysis of grade 1.2162

C(%) Si(%) Mn(%) P(%) S(%) Cr(%)

0.18-0.24 0.15-0.35 1.10-1.40 Max 0.030 Max 0.030 1.00-1.30

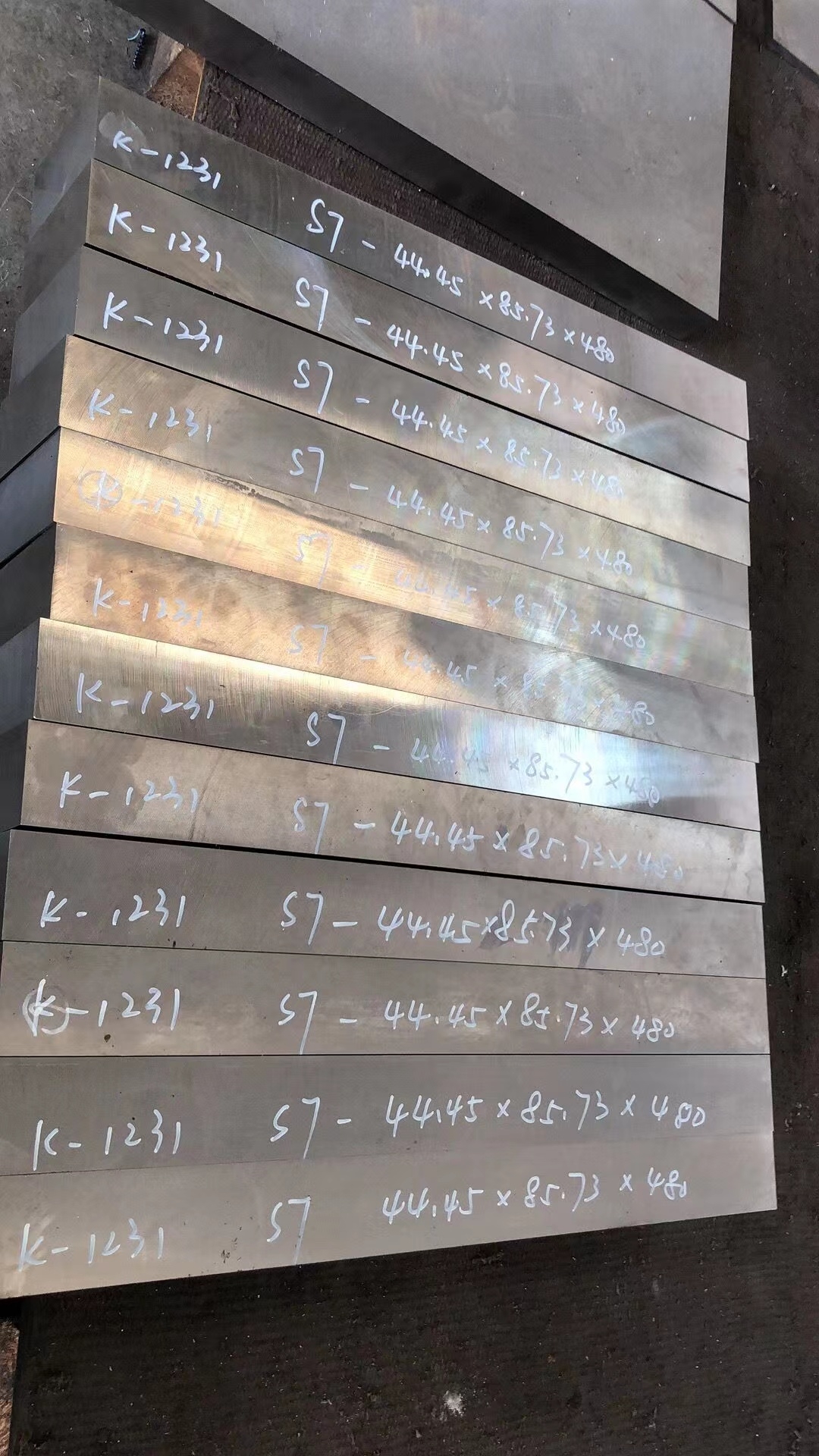

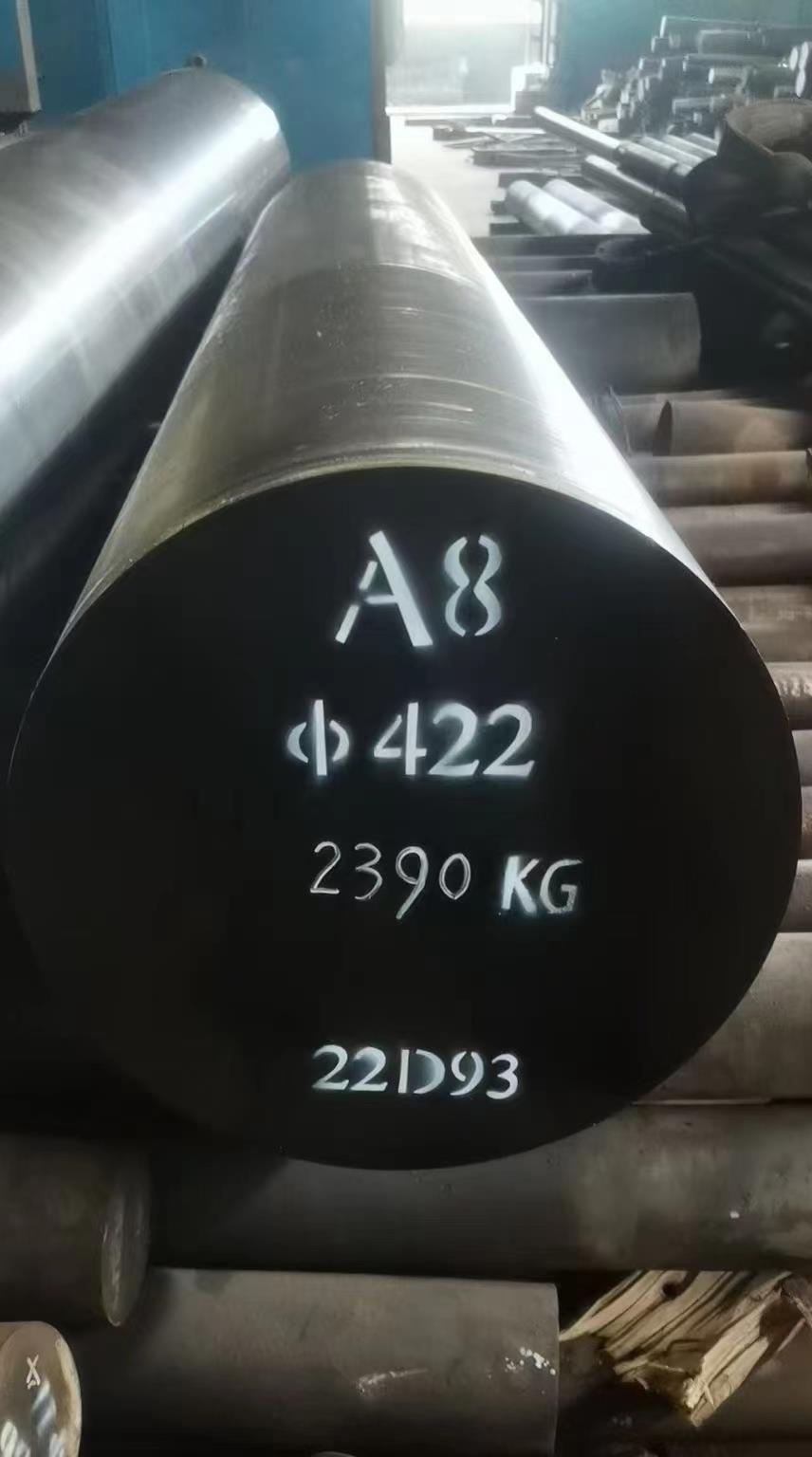

Product range

Round bars: D10 – D615

Blocks: 510×1010

Metal sheets: s.5 – s.150

We will deliver any semi-finished products from the above mentioned dimensions. Other dimensions, except for given stock supplies, have to be consulted with us.

HEAT TREATMENT:

Soft annealing:

670 to 710 °C for about 2 to 5 hours

slow controlled cooling, further cooling in air, max. 205 HB

Carburising:

900 to 950 °C. The choice of the carburising means and carburising temperature depends on the desired surface carbon content, the carburising graph and the required case depth.

Application:

870 to 930 °C in powder/salt bath, cooling in oil/warm bath at 160 to 250 °C

Intermediate stress-relieving heat treatment:

630 to 650 °C, about 2 to 4 hours with slow furnace cooling

Preheating:

350 °C depending on dimensions

Hardening:

curing temperature 810 to 840 °C in oil of ~ 60 °C warmth

Cooling:

down to about 100 °C in oil, then in air to about 50 °C

Tempering:

1 hour per 20 mm part thickness, at least 2 hours