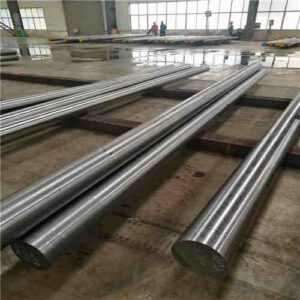

16NiCrS4 1.5715 Case Hardening Steels

16NiCrS4 1.5715 Case Hardening Steels

Grade :16NiCrS4 Number: 1.5715 Classification: Alloy special steel

Supplying Size:Forging: 80-600mm

Standard:

EN 10277-4: 2008 Bright steel products. Technical delivery conditions. Case hardening steels

EN 10084: 2008 Case hardening steels. Technical delivery conditions

Equivalent grades of steel 16NiCrS4 (1.5715)

| EU | USA | Italy | Sweden |

| EN | – | UNI | SS |

| 16NiCrS4 | 3115 | 16NiCrS4 | SS2511 |

Chemical composition %

| C | Si | Mn | Ni | P | S | Cr |

| 0.13 – 0.19 | max 0.4 | 0.7 – 1 | 0.8 – 1.1 | max 0.025 | 0.02 – 0.04 | 0.6 – 1 |

Mechanical properties of 16NiCrS4 (1.5715)

| Steel name | Steel number | Thickness mm | +A + turned (+A +SH) Hardness HBW max. | +A + cold drawn (+A +C) Hardness HBW max. | +FP + turned (+FP +SH) Hardness HBW | +FP + cold drawn (+FP +C) Hardness HBW |

| 16NiCrS4 | 1.5715 | ≥5 ≤10 | – | 270 | – | – |

| > 10 ≤16 | – | 260 | – | – | ||

| > 16 ≤40 | 217 | 255 | 156 to 207 | 156 to 245 | ||

| > 40 ≤63 | 217 | 255 | 156 to 207 | 156 to 240 | ||

| >63 ≤100 | 217 | 255 | 156 to 207 | 156 to 240 |

+A= soft annealed

+FP= treated to ferrite-pearlite structure and hardness range

Finished condition

- a) drawn, symbol +C;

- b) turned, symbol +SH;

- c) ground, symbol +SL.

Heat Treatment

| Process | time | Temperatures |

| Austenitizing | 30 – 35 min | 880℃ |

| Carburizing | 880 – 980℃ | |

| Core-hardening | 850 – 890℃ | |

| Case-hardening | 780 – 820℃ | |

| Tempering | 1 h minimum | 150 – 200℃ |

Introduction

16NiCrS4 is a low-alloy (chrome-nickel) case-hardening steel. Machining of larger components with complex shape, e.g. gear wheels, is facilitated by the steel being soft-annealed after forging to achieve a hardness of 217 HB or below.

16NiCrS4 is standardised in SS-EN ISO 683 – 3. The hardness as supplied corresponds to “+A” (soft annealed). The (discontinued) SS-designation is 2511.

Base hardenability is an important characteristic of case-hardening steels since it determines core properties after hardening and tempering. It is normally specified in terms of a Jominy diagram, which gives the hardness distribution as read off on a sample which has been hardened by directing a spray of water at its one end according to a standardised procedure. The addendum “+HL” after the steel name signifies that the analysis is controlled such that the Jominy curve lies between limits which are stipulated in the SS-EN ISO 683 – 3 standard.