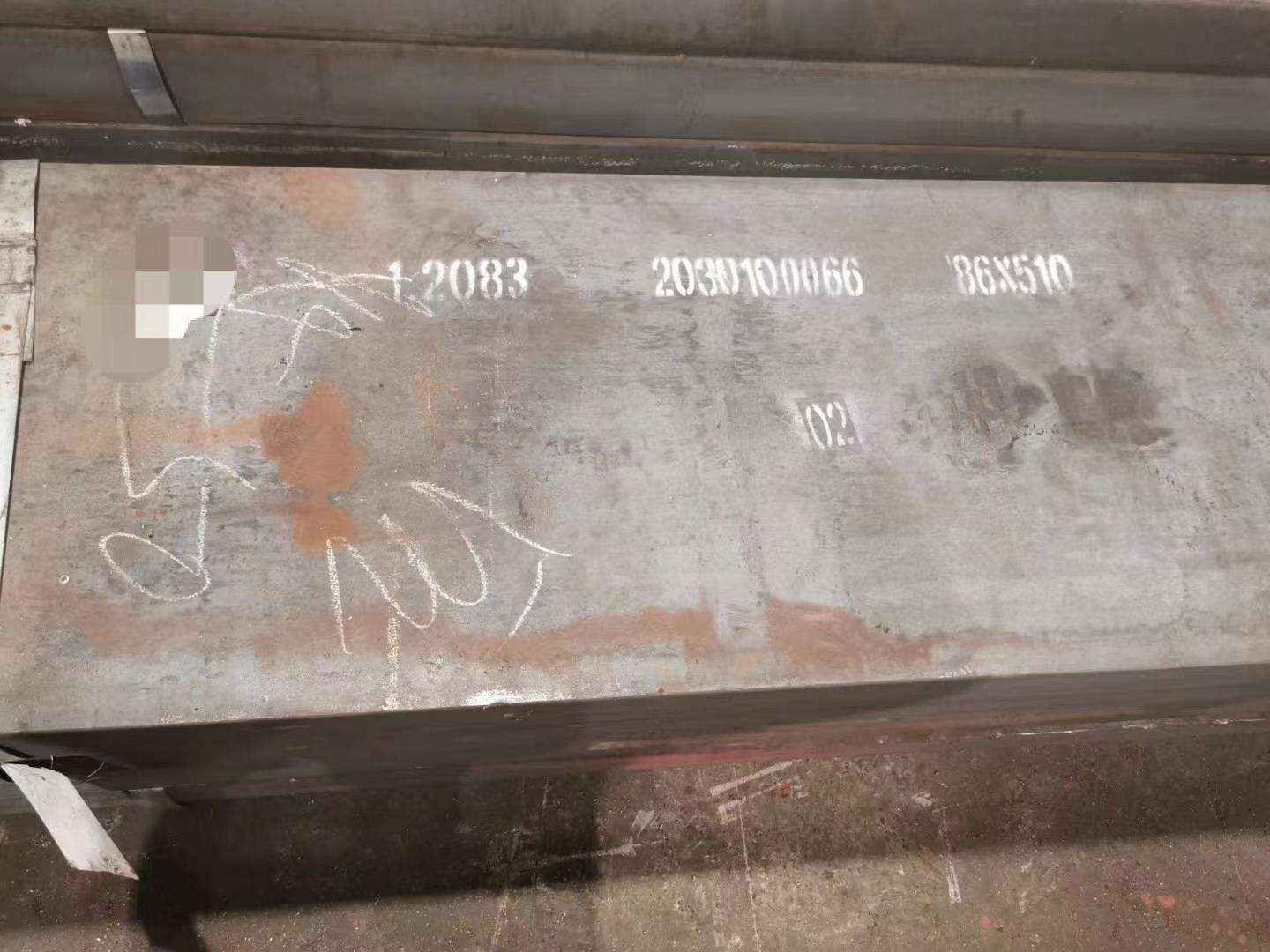

1.4528 Cold Rolled Stainless Steel Sheet

1.4528 Cold Rolled Stainless Steel Sheet

1.4528 Introduce

W.-Nr. 1.4528 ( DIN X105CrCoMo18-2 ) High carbon martensitic stainless chromium steel with cobalt, molybdenum and vanadium is equivalent to BOHLER N690 or written as N690Co. It’s a similar version of Japanese VG10 steel.

Back to Top

1.4528 Applications

Hardened cutting tools with excellent edge-holding property, such as knive blades, cutting surgical instruments, rotary knives for the meat processing industry, plate and knive-edge fulcrums, corrosion resistant roller bearings, valve needles and pistons for refrigerating machines.

Back to Top

1.4528 Advantage

Hardness approx. 60 HRC

Very high resistance to rust

Very good to polish

High edge retention on sharpening level B / C

Recommendation for outdoor knives, camping knives, pocket knives, hunting knives, etc.

NOT suitable for Damascus steel!

Hardening: 1050 ° / tempering at 180 ° C for 2 x 2 hours (in between quenching in cold water) gives approx. 60 HRC.

Back to Top

CHEMICAL COMPOSITION (average %)

| C | Si | Mn | Cr | Mo | V | Co |

| 1.08 | 0.40 | 0.40 | 17.30 | 1.10 | 0.10 | 1.50 Back to Top |

PRODUCT DESCRIPTION

Hardened cutting tools with excellent edge-holding property, such as knive blades, cutting surgical instruments, rotary knives for the meat processing industry, plate and knive-edge fulcrums, corrosion resistant roller bearings, valve needles and pistons for refrigerating machines.

Back to Top

PROPERTY FEATURES

Martensitic chromium steel with cobalt, molybdenum and vanadium addition. For tools and components which can be hardened to very high hardness levels. Surface finish required for good corrosion resistance: fine ground or polished.

Back to Top