301 S30100 1.4310 SUS301 Stainless Steel

301 S30100 1.4310 SUS301 Stainless Steel

301 is an austenitic chromium-nickel stainless steel. This alloy is nonmagnetic in the annealed condition,but becomes magnetic when cold worked. Within the scope of the ASTM 301 pecification, chemical composition and processing moditications can result in a wide range of engineered material properties targeted at specific applications. 301 is available in the annealed as well as a variety of temper-rolled conditions.

Applications

High strength and excellent corrosion resistance make 301 Stainless Steel useful for a wide variety of applications.Typical uses include aircraft structural parts,trailer bodies, diaphragms, utensils, architectural and automotive trim,automobile wheel covers,roof drainage products, tablewear, storm door frames,conveyor belts,sinks,subway cars and appliances.

Grade comparison for grade 301 stainless steel

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 301 | S30100 | 301S21 | – | 1.4310 | X10CrNi18-8 | 2331 | SUS 301 |

Chemical Properties:

| % | Cr | Ni | C | Si | Mn | P | S | N | |

| 301 | Min: | 16 | 6 | – | – | – | – | – | – |

| Max: | 18 | 8 | 0.15 | 1.00 | 2.0 | 0.045 | 0.030 | 0.10 |

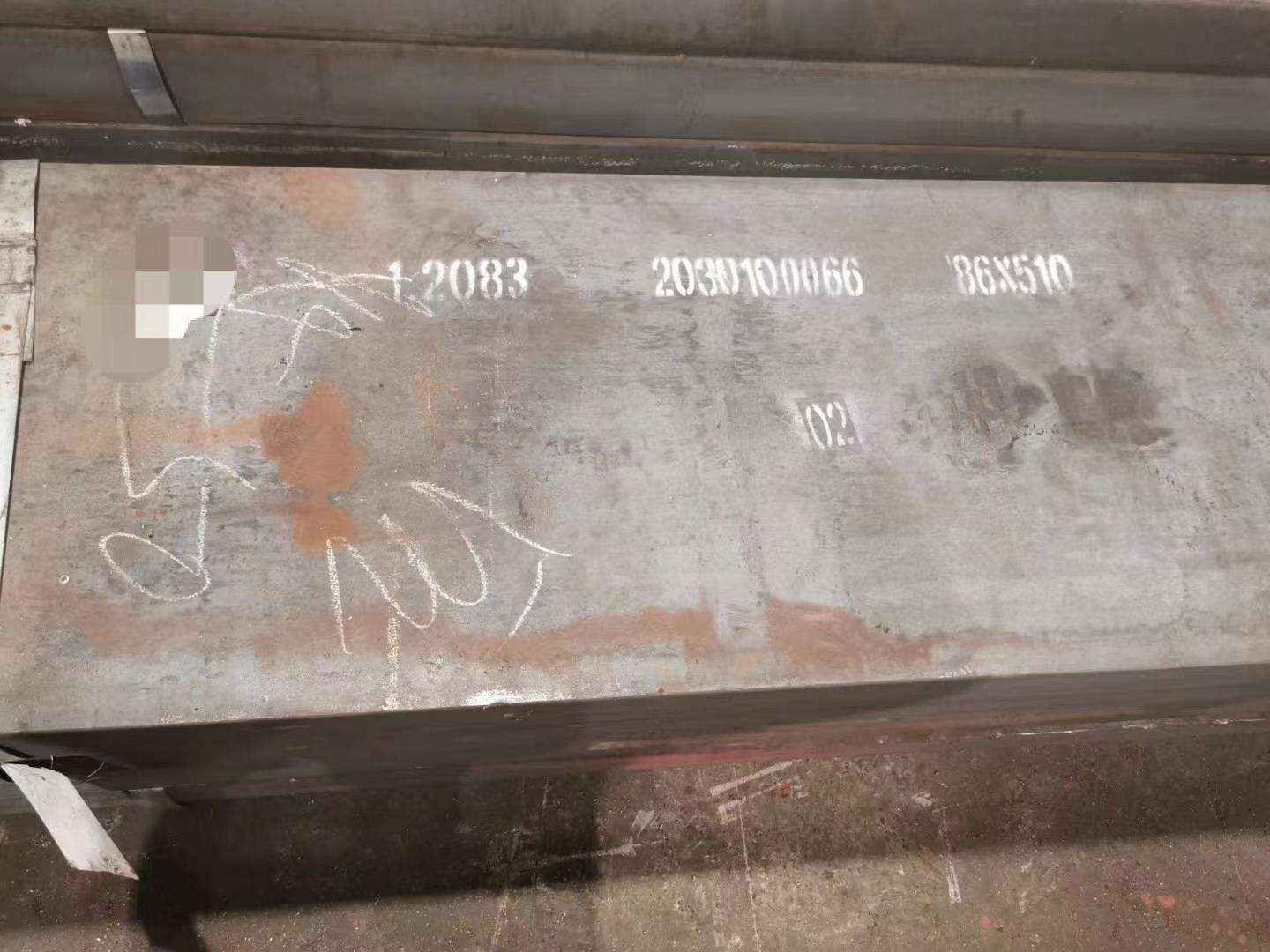

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

5 +AT: Solution annealed

6 +P: Precipitation hardened

Suface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

Mechanical Properties:

| Grade/Temper | Tensile Strength ksi (min.) | Yield Strength 0.2% ksi (min.) | Elongation -% in 50 mm (min.) |

| 301 1/4 | 125 | 75 | 25 |

| 301 1/2 | 150 | 110 | 18 |

| 301 Full Hard | 185 | 140 | 9 |

CORROSION RESISTANCE

Stainless 301 Stainless Steel exhibits corrosion resistance comparable to Stainlesss 302 and 304 in most mild service conditions.Resistance to food service requirements and atmospheric corrosion is excellent. Stress cracking resistance is similar to Stainless 304.The optimal corrosion resistance is obtained in the cold worked then annealed condition. When Stainless 301 is heated or cooled slowly through a temperature range of 800-1600 F(427-871C) without subsequent annealing, it may undergo carbide precipitation that may result in intergranular corrosion.

OXIDATION RESISTANCE

The maximum temperature to which Stainless 301 can be exposed continuously without appreciable scaling is about 1600 F(871C). For intermittent exposure,the maximum exposure temperature is about 1450 F(788 OC).

HEAT TREATMENTS

Stainless 301 is non-hardenable by heat treatment.

Annealing:Heat to 1900-2050 F(1038-1121 C),then water quench.

Stress Relief Annealing:Heat to 500-900 F(260-482C),then air cool.

COLD WORKING

High hardness and strength for structural applications are achieved through cold working. In addition to the annealed condition 110 ksi.(758 MPa)minimum tensile strength,Stainless 301 strip is normally produced in various cold-rolled tempers up to full hard 185 ksi.(1276 MPa)minimum tensile strength.

FORMABILITY

Stainless 301 can be readily formed and drawn.Due to its high work-hardening rate,intermediate annealing may be necessary for severe drawing and forming operations.Stainless 301 may not be suitable in certain severe forming applications where multiple forming operations are required.