Super Duplex F55 S32760 Stainless Steel

F55 S32760 Stock Range

We stock a comprehensive range of round bar sizes between 10mm and 500mm diameter. We can also supply flat bar, rings, blocks and slabs. Availability Bar, forgings, sheet, plate, pipe, tube, closed die forgings, flanges and welding consumables.

F55 S32760 Industry Specifications

- ASTM A479

- Werkstoff Nr. 1.4501

- Nace MR0175/ISO15156

- Norsok M630

- EN 10088-3, ASTM A276, ASTM A182–11A

- UNS S32760 in various ASTM product form specifications

- EN 10088-3 1.4501 (Grade X2CrNiMoCuWN25-7-4)

- NORSOK MDS D51 to D55, D57 & D58

- ASTM A182 F55

- NACE MR01-75 (latest revision) / ISO 15156

Material may also be supplied to Customer specifications, subject to enquiry

F55 S32760 Chemical Composition (weight %)

| C | Si | Mn | S | P | Cr | Ni | Mo | N | Cu | W |

| 24,00 | 6,00 | 3,00 | 0,20 | 0,50 | 0,50 | |||||

| 0,030 | 1,00 | 1,00 | 0,010 | 0,030 | 26,00 | 8,00 | 4,00 | 0,30 | 1,00 | 1,00 |

F55 S32760 Mechanical Property

| Mechanical Property Requirements – Annealed condition | ||||

| Yield | Tensile Strength | Elongation | Charpy Impact @ Rt J | Hardness |

| >550Mpa (80KSI) | 730 – 930Mpa | 25% | 100 | 290HB Max |

| (106 – 135KSI) | ||||

F55 S32760 Material Condition

Our material is supplied in the hot worked and annealed condition. Material is supplied with corrosion testing in accordance with ASTM G48A.

F55 S32760 Quick Facts

- Known as Super Duplex F55

- Available in the hot worked annealed condition

- Excellent corrosion resistance to a range of media

- Resistant to pitting and crevice corrosion in marine and chloride containing environments

- High strength compared to austenitic and 22% chrome duplex stainless steels

Super Duplex UNS S32760 is among the most common super duplex grade in the market. UNS S32760 is a duplex stainless steel especially designed for service in aggressive chloride-containing environments and has additions of W and Cu compared to UNS S32750.

Alloy S32760 is a super duplex stainless steel which combines high mechanical strength and good ductility. It has excellent corrosion resistance in a range of environments. It is usually supplied in the annealed condition and cannot be age hardened however cold working can give stronger surface strengths.

F55 S32760 Typical Applications

Bolts and Fasteners, pumps, valves, vessels, wellhead equipment, subsea equipment, propellers and shafts. Pumps, valves, chokes, Xmas trees, pipework / flanges, bolting, connectors & manifolds. In oil and gas industry. Equipment in defence, chemical and marine industries.

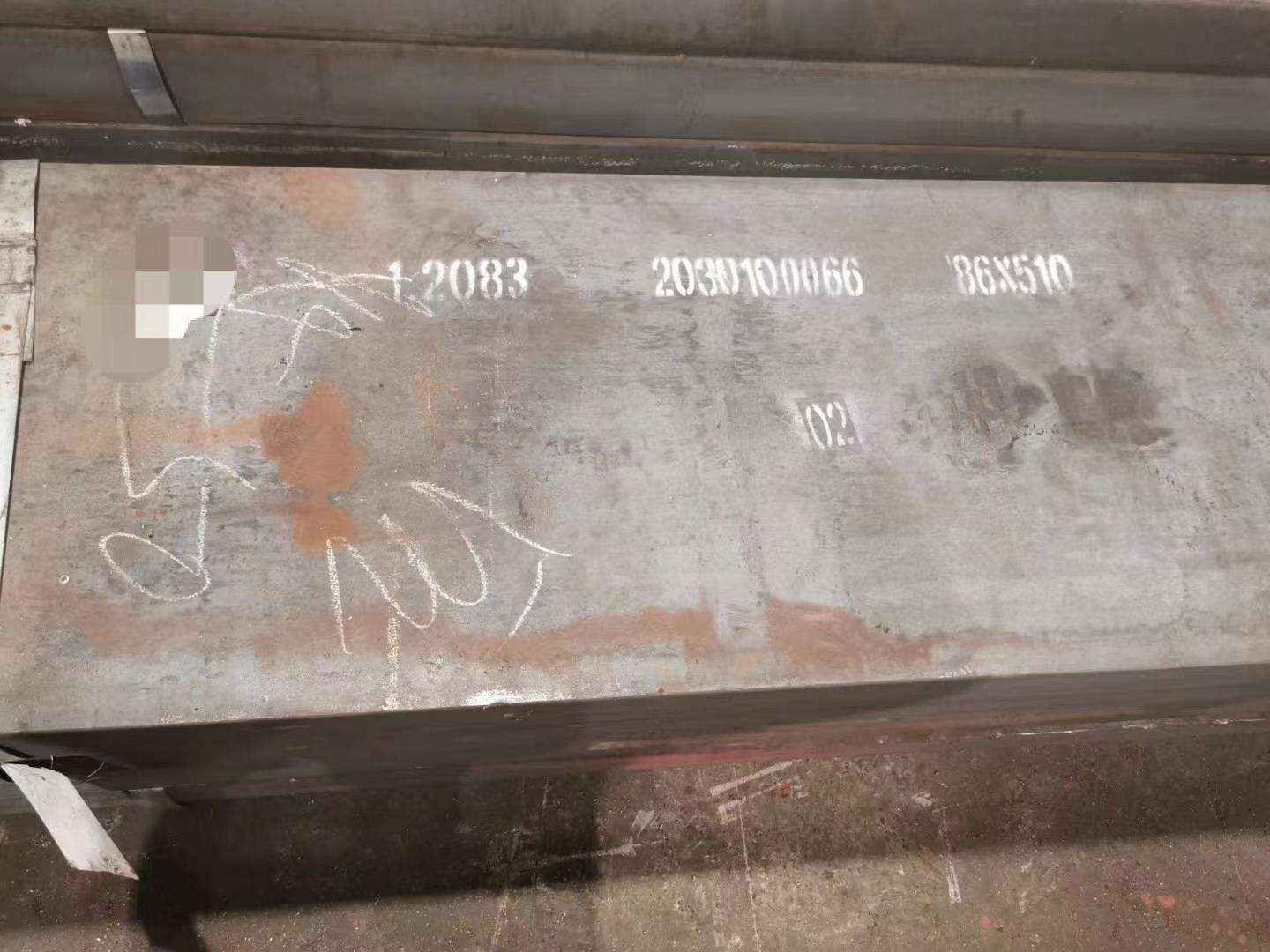

F55 S32760 Product Description

Material to UNS S32760 (and the other specifications listed below) is described as a super duplex stainless steel with a microstructure of 50:50 austenite and ferrite. The steel combines high mechanical strength (typically up to 600 MPa yield strength) and good ductility with outstanding corrosion resistance to marine environments and a wide, diverse range of oil & gas production environments. The alloy is supplied with a PREN (Pitting Resistance Equivalent) at >= 40.0 which guarantees high resistance to pitting corrosion. In addition, the steel offers high resistance to crevice corrosion and stress corrosion cracking. Ambient and sub-zero (down to minus 50 °C) notch ductility is good. These attributes mean that this super duplex steel can be used successfully as an alternative to 300 series stainless steel (such as type 316), standard 22% Cr duplex steel and precipitation hardening stainless steels. Where appropriate the alloy can be considered in lieu of more costly Grade 5 titanium or nickel based alloys.

All material we supply has full traceability with inspection certification in accordance with BS EN 10402 3.1. We can supply material with BS EN 10402 3.2 inspection certification on request. All information included in this sheet is intended as a guide only and is correct to the best of our knowledge.

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

Mill test certificate

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.