1.4935, X20CRMOWV12-1, AISI 422 – CREEP RESISTING STEEL

Material 1.4935 High-temperature resisting steel and alloy. The material 1.4935 is a highly heat-resistant martensitic steel. This steel can be used up to a maximum temperature of about 650 °C / 1202 °F. Typical application for the turbine is 1.4935.

Standards

| HDIN / EN | US-Standard |

| X20CrMoWV12-1 | AISI 422 UNS S42200 |

Chemical Composition

| Standard | C: | Si: | Mn: | P: | S: | Cr: | Mo: | Ni: | V: | W: | Cu: |

| EN | 1.4935, X20CrMoWV12-1 | ||||||||||

| 0.17-0.24 | 0.1-0.5 | 0.3-0.8 | <0.025 | <0.015 | 11.0-12.5 | 0.8-1.2 | 0.3-0.8 | 0.25-0.35 | 0.4-0.6 | – | |

| JIS | SUH616 | ||||||||||

| 0.20-0.25 | <0.5 | 0.5-1.0 | <0.04 | <0.03 | 11.0-13.0 | 0.75-1.25 | 0.5-1.0 | 0.2-0.3 | 0.75-1.25 | <0.3 | |

| ASTM | AISI 422 / AISI 616 – S42200 | ||||||||||

| 0.20-0.25 | <0.75 | <1.0 | <0.04 | <0.03 | 11.0-12.5 | 0.75-1.25 | 0.5-1.0 | 0.15-0.30 | 0.75-1.25 | <0.5 | |

APPLICATIONS

Jet engine components

High temperature fasteners, springs

Non-magnetic cryogenic equipment

1.4935, X20CRMOWV12-1, AISI 422 – CREEP RESISTING STEEL, DATA ACCORDING TO EN 10088-3:2014 AND EN 10302

1.4935, X20CrMoWV12-1 – description

Creep resistant steel used for thermal engine components in power plants, mainly turbine blades, but fasteners as well. Hardenable. Max temperature for continous operating is 580 °C.

Chrome-nickel steel with an austenitic structure with carbides. Alloying additions of molybdenum, vanadium and tungsten increase the melting temperature, thus having a positive effect on creep resistance.

The steel is hard to weld. It is assigned to welding group 7.2 according to ISO/TR 20172.

Physical and mechanical properties

1.4935 – physical properties and indicative mechanical properties:

Density: 7.7 g/cm3

Linear expansion coefficient: 10.5-12.5 *10-6m/(m*K)

Thermal conductivity: 24 W/(m*K)

Specific heat capacity: 460 J/(kg*K)

Young’s modulus: 216 GPa

Electrical resistivity: 0.6 µΩ*m

Tensile strength Rm: > 600 MPa

Creep limit for max elongation 0.2% Rp0.2: > 800 MPa

Creep-rupture strength Ru: > 275 MPa; 500 °C; 100000 h

Creep limit for max elongation 0.2% Rp0.2 – high temperature test:

Testing temperature: 400 °C – > 420 MPa

Testing temperature: 500 °C – > 335 MPa

Mechanical properties of +QT700 class forgings:

Ambient temperature:

Re: > 500 MPa

Rm: 700-850 MPa

A: 15 %

Yield strength Re in high temperature:

Testing temperature: 50 °C – > 465 MPa

Testing temperature: 100 °C – > 460 MPa

Testing temperature: 150 °C – > 445 MPa

Testing temperature: 200 °C – > 430 MPa

Testing temperature: 250 °C – > 415 MPa

Testing temperature: 300 °C – > 390 MPa

Testing temperature: 350 °C – > 380 MPa

Testing temperature: 400 °C – > 360 MPa

Testing temperature: 450 °C – > 330 MPa

Testing temperature: 500 °C – > 290 MPa

Testing temperature: 550 °C – > 250 MPa

Mechanical properties of +QT800 class forgings:

Ambient temperature:

Re: > 600 MPa

Rm: 800-950 MPa

A: 14 %

Yield strength Re in high temperature:

Testing temperature: 50 °C – > 585 MPa

Testing temperature: 100 °C – > 560 MPa

Testing temperature: 150 °C – > 545 MPa

Testing temperature: 200 °C – > 530 MPa

Testing temperature: 250 °C – > 505 MPa

Testing temperature: 300 °C – > 480 MPa

Testing temperature: 350 °C – > 450 MPa

Testing temperature: 400 °C – > 420 MPa

Testing temperature: 450 °C – > 380 MPa

Testing temperature: 500 °C – > 335 MPa

Testing temperature: 550 °C – > 280 MPa

Heat treatment and working

Recommended working and heat treatment parameters for 1.4935 alloy:

Quenching: 1020-1070 °C

Tempering: 680-780 °C

Replacements, equivalents and other designations:

1.4935, X22CRMOWV12-1, SUH616, 20VNIWMOCR120, AISI 422, AISI 616, S42200, EW 4935, T502, 56B.I.; DE 4935, HWMOV3, GRADE 616

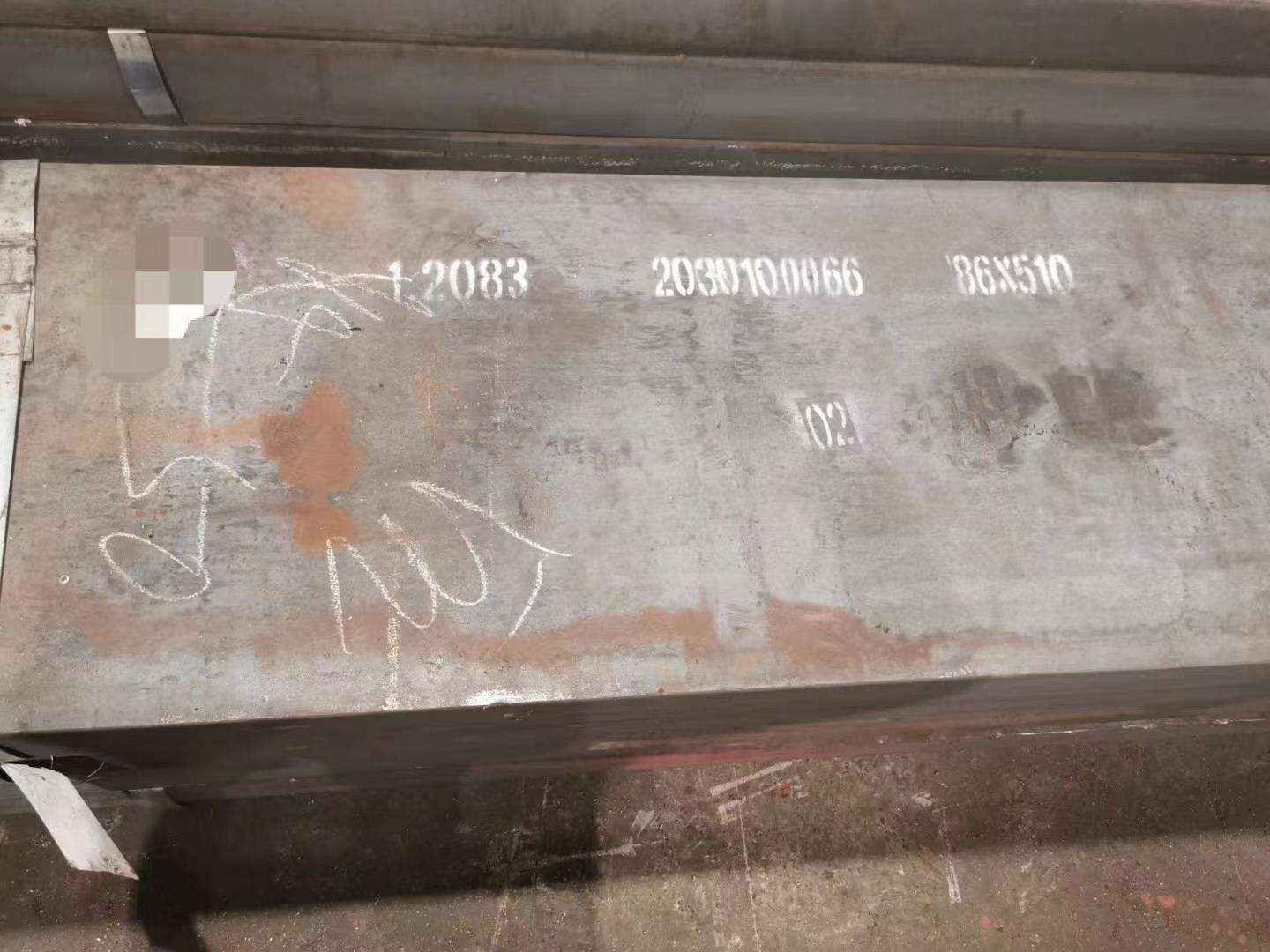

Machining Status

raw

Rough Turning

Finished

Processed according to technical drawing