SUP7 1.5028 DIN 56Si7 SAE 9260H 60Si2Mn Spring Steel

SUP7 Mat.No. 1.5028 DIN 56Si7 SAE 9260H 60Si2Mn Spring Steel p1

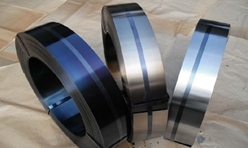

Mat.No. 1.5028 DIN 56Si7 SAE 9260H 60Si2Mn Spring Steel Strip

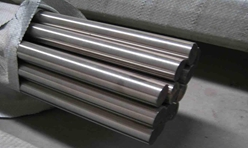

Mat.No. 1.5028 DIN 56Si7 SAE 9260H 60Si2Mn Spring Steel Wire

1 Sup7 Introduction:

JIS SUP7 Steel is a high quality Alloy Spring Steel, It belong to the high quality high carbon alloy Spring Steel. Quenched & Tempered Hardness is 28-34 HRc. SUP 7 steel Annealing delivery hardenss less than 250HB.

Back to Top

2 SUP7 Applications:

Steel grade for laminated springs thickness above 7 mm for trucks and railway vehicles, coiled and threaded springs.

Back to Top

3 Quality Standard:

JIS G4801 2005 Spring Steels

BS EN 10089 2002 Hot rolled steels for quenched and tempered springs

ASTM A29 Standard Specification Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements

Back to Top

4 All Grades Comparison:

Back to Top

5 SUP7 Chemical Composition(%)

| Steel Grade | C | Si | Mn | P | S |

|---|---|---|---|---|---|

| 9260 | 0.56-0.64 | 1.90-2.20 | 0.75-1.00 | 0.035 max | 0.040 max |

| 56Si7 | 0.52-0.60 | 1.60-2.00 | 0.60-0.90 | 0.025 max | 0.025 max |

| SUP7 | 0.56-0.64 | 1.80-2.20 | 0.70-1.00 | 0.030 max | 0.030 max |

| 60Si2Mn | 0.56-0.64 | 1.50-2.00 | 0.70-1.00 | 0.035 max | 0.035 max |

Back to Top

6 HEAT TREATMENT:

- FORGING:Hot forming temperature: 1050-850oC.

- SOFT ANNEALING: Heat to 640-680oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 255.

- HARDENING: Harden from a temperature of 830-860oC followed by oil quenching.

- TEMPERING:Tempering temperature: 350-550oC, air.

Back to Top

7 Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Back to Top