Spring Steel Strip and Plate

Spring Steel Strip and Plate

1.Description

Spring Steel is typically used because of its’ high yield strengths, resistance to deformation and its ability to return to its original shape.

Back to Top

2.All Grades Comparison

| GB | ASTM | JIS | EN | DIN |

|---|---|---|---|---|

| 55 | 1055 | / | CK55 | 1.1204 |

| 60 | 1060 | / | CK60 | 1.1211 |

| 70 | 1070 | / | CK67 | 1.1231 |

| 75 | 1075 | / | CK75 | 1.1248 |

| 85 | 1086 | SUP3 | CK85 | 1.1269 |

| T10A | 1095 | SK4 | CK101 | 1.1274 |

| 65Mn | 1066 | / | / | / |

| 60Si2Mn | 9260 | SUP6,SUP7 | 61SiCr7 | 60SiCr7 |

| 50CrVA | 6150 | SUP10A | 51CrV4 | 1.8159 |

Back to Top

3.Quality Standard

DIN 17222 Cold Rolled Steel Strips for Springs Technical Conditions of Delivery

BS EN 10132 Cold rolled narrow steel strip for heat treatment. Technical delivery conditions

Back to Top

4.Chemical Composition(%)

| Steel Grade | C | Mn | Si | P | S | Cr | Ni | B | Cu | Mo | V |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 55 | 0.52-0.60 | 0.50-0.80 | 0.17-0.37 | 0.035 max | 0.035 max | 0.25 max | 0.30 max | / | 0.25 max | / | / |

| 65 | 0.62-0.70 | 0.50-0.80 | 0.17-0.37 | 0.035 max | 0.035 max | 0.25 max | 0.25 max | / | 0.25 max | / | / |

| 70 | 0.62-0.75 | 0.50-0.80 | 0.17-0.37 | 0.035 max | 0.035 max | 0.25 max | 0.25 max | / | 0.25 max | / | / |

| 75 | 0.72-0.80 | 0.50-0.80 | 0.17-0.37 | 0.035 max | 0.035 max | 0.25 max | 0.30 max | / | 0.25 max | / | / |

| 85 | 0.95-1.04 | 0.40 max | 0.35 max | 0.025 max | 0.025 max | / | / | / | / | / | / |

| 65Mn | 0.62-0.70 | 0.90-1.20 | 0.17-0.37 | 0.035 max | 0.035 max | 0.25 max | 0.25 max | / | 0.25 max | / | / |

| 60Si2Mn | 0.56-0.64 | 0.70-1.00 | 1.50-2.00 | 0.035 max | 0.035 max | 0.35 max | 0.25 max | / | 0.25 max | / | / |

| 50CrVA | 0.46-0.54 | 0.50-0.80 | 0.17-0.37 | 0.025 max | 0.025 max | 0.80-1.10 | 0.35 max | / | 0.25 max | / | 0.10-0.20 |

Back to Top

5.Mechanical Properties(Quenched and Tempered Condition)(T=20°C if not differently stated)

| Steel Grade | Tensile Strength Rm (Mpa) | Yield Strength Rp0.2 (Mpa) | Elongation A5 (%) | Area Reduction Ratio C (%) |

|---|---|---|---|---|

| 65 | 980 min | 785 min | 9 min | 35 min |

| 70 | 1030 min | 835 min | 8 min | 30 min |

| 85 | 1130 min | 980 min | 6 min | 30 min |

| 65Mn | 980 min | 785 min | 8 min | 30 min |

| 60Si2Mn | 1275 min | 1180 min | 5 min | 25 min |

| 50CrVA | 1275 min | 1130 min | 10 min | 40 min |

Back to Top

6.Delivery Conditions

Cold Rolled only

Cold Rolled+Soft Annealed (G)

Cold Rolled+Soft Annealed+Cold Rolled (G+K)

Cold Rolled+Hardened+Tempered (H+A)

Back to Top

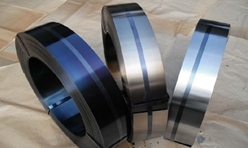

7.Surface Conditions

Grey Blue (GR)

Bright (BK)

Polished (P)

Polished and Colour Tempered (P+AF)

Back to Top

8.Heat Treatment

| Steel Grade | Quenching Temperature (°C) ( | Media | Tempering Temperature (°C) |

|---|---|---|---|

| 65 | 840 | oil | 500 |

| 70 | 830 | oil | 480 |

| 85 | 820 | oil | 480 |

| 65Mn | 830 | oil | 540 |

| 60Si2Mn | 870 | oil | 480 |

| 50CrVA | 850 | oil | 500 |

Back to Top

9.Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Back to Top